Understanding Bearing Accuracy and Tolerance Classes

Bearing accuracy and tolerance play pivotal roles in ensuring the optimal performance and longevity of machinery components. By meticulously adhering to standardized measurements and classifications, engineers and manufacturers can achieve precise fits and minimize operational issues such as vibration and misalignment. Here, we delve into the key components of bearing accuracy and tolerance, providing insights into boundary dimension accuracy, machining accuracy, running accuracy, and the internationally recognized bearing tolerance classes.

Boundary Dimension Accuracy

Boundary dimension accuracy focuses on critical dimensions such as bore diameter (d), outer diameter (D), and nominal widths of the inner (B) and outer (C) rings. Deviations from specified dimensions can significantly affect shaft and housing fits. Measurement parameters including dimensional deviation (∆dmp), single-plane mean bore deviation (∆Dmp), and inner and outer ring width deviations (∆Bs and ∆Cs) are employed to ascertain dimensional accuracy. Understanding these parameters aids in navigating dimension series and determining suitable fits, guided by bearing tolerance classes standardized by ISO, ABMA, and JIS.

Machining Accuracy

Machining accuracy pertains to variations in boundary dimensions among individual bearings, reflecting the precision of the manufacturing process. Parameters such as bore diameter variation in a single radial plane (Vdp), outside diameter variation (VDp), mean bore diameter variation (Vdmp), and mean outside diameter variation (VDmp) are scrutinized to assess machining accuracy. Additionally, variations in inner (VBs) and outer (VCs) ring widths are considered. This scrutiny aids in selecting appropriate tolerances for shafts and housings, ensuring optimal performance.

Running Accuracy

Running accuracy evaluates the runout of rotating elements, encompassing radial and axial runout of inner and outer rings. Parameters such as radial runout of assembled bearing inner ring (Kia), radial runout of assembled bearing outer ring (Kea), and side face runout with reference to bore of the inner ring (Sd) are measured to gauge running accuracy. Precise running accuracy measurements mitigate excessive vibration and misalignment issues, contributing to smooth operation and extended component lifespan.

Bearing Tolerance Classes

ISO, ABMA, and JIS provide internationally standardized bearing tolerance classes, delineating allowable error limitations. These classes, ranging from 0 to 6, denote varying levels of accuracy and precision. Classifications encompass all aspects of accuracy relative to bearing size, with higher numbers indicating superior accuracy. Understanding and adhering to these tolerance classes facilitate the selection of bearings tailored to specific application requirements, ensuring optimal performance and reliability.

In conclusion, meticulous attention to bearing accuracy and tolerance is essential for achieving optimal machinery performance and reliability. By comprehensively understanding boundary dimension accuracy, machining accuracy, running accuracy, and bearing tolerance classes, engineers and manufacturers can make informed decisions to mitigate operational issues and enhance overall efficiency and longevity.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

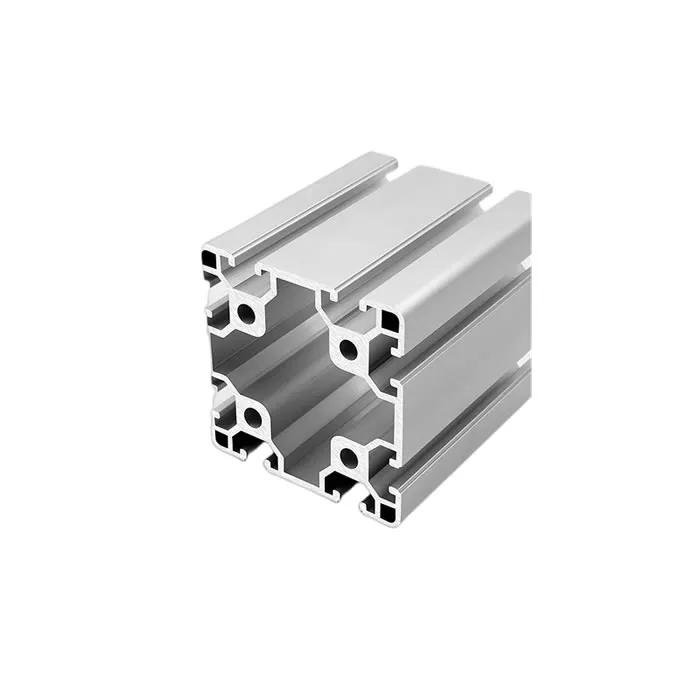

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd