Effective Solutions for Removing Stripped Screws: Prevention and Removal Techniques

Introduction

Removing screws from wood is usually a straightforward task, but stripped screws can pose challenges due to worn-out drive heads. However, several methods can effectively prevent and address this issue. This guide explores preventative measures and removal techniques to assist in overcoming stripped screws.

Preventing Stripped Screws

Preventing stripped screws involves understanding the factors that contribute to their occurrence and avoiding common mistakes:

1. Proper Tool Selection: Use the correct size and type of screwdriver for the screw head to prevent slippage and stripping.

2. Appropriate Tool Usage: Avoid using power drills at high speeds or incorrect angles, as this can increase the likelihood of stripping.

3. Controlled Torque Application: Apply moderate torque and ensure correct insertion angle to prevent stripping.

4. Drive Type Consideration: Some drive types, such as slotted drives, are more prone to stripping. Choose suitable drive types based on the application.

Methods for Removing Stripped Screws

Various techniques can be employed to remove stripped screws effectively:

1. Rubber Bands:

Using wide rubber bands adds traction and grip for the screwdriver. Place the rubber band over the stripped screw, insert the screwdriver, and slowly turn to loosen the screw. Steel wool can also provide traction.

2. Manual Screwdriver:

Using a manual screwdriver offers increased torque and control compared to an electric drill. Lean into the screw and apply pressure while turning to avoid further stripping.

3. Adjust Driver Bit Size:

Try using a driver bit slightly larger than the original screw size to achieve a better fit and grip.

4. Stripped Screw Extractor:

Screw extractors are specialized attachments for drills, available in various sizes. Drill into the screw head to create a hole, then insert the extractor and remove the screw.

5. Pliers:

If space permits, grip the screw head with pliers and twist to loosen. Vice grips or locking pliers can provide a firm grasp for removal.

6. Tap Screwdriver With a Hammer:

Tap a manual screwdriver into the screw head with a light hammer to create a deeper grip. Twist the screwdriver while inserted to remove the screw.

7. Add an Abrasive:

Apply powder or liquid abrasive to the screw head for increased friction and grip during removal.

8. Cut a Slot:

Use a rotary cutting tool or multi-tool to cut a slot into the screw head. Insert a flathead screwdriver into the groove to turn and remove the screw.

Conclusion

Stripped screws can present challenges, but with the right techniques, they can be effectively prevented and removed. By implementing preventative measures and employing suitable removal methods, you can overcome the issue of stripped screws and proceed with your woodworking projects smoothly.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

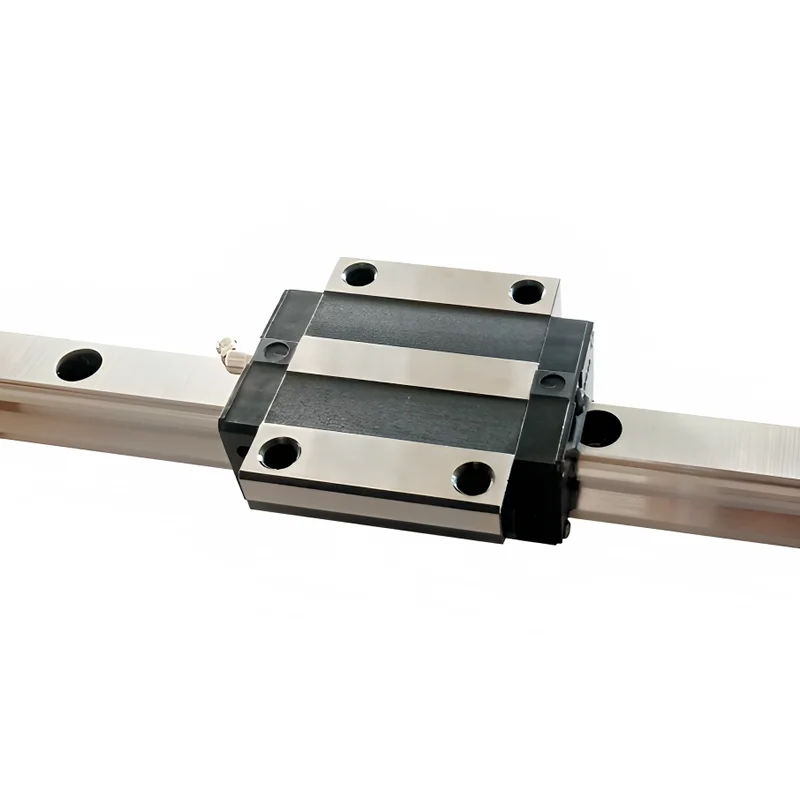

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS