What Is Industrial Automation and Why Is It Important

Industrial automation, encompassing technologies such as industrial robots, machine vision systems, and advanced sensors, revolutionizes manufacturing by

automating tasks ranging from assembly to quality control. This article delves into the essence of industrial automation, its pivotal role in modern manufacturing, and the benefits it offers to businesses and the economy.

Industrial automation utilizes sophisticated technologies to control and automate manufacturing processes, enhancing efficiency, reducing costs, and elevating

product quality. It fosters a safer working environment by mitigating workplace hazards, consequently improving the overall safety of manufacturing facilities.

Various types of industrial automation exist, catering to different manufacturing needs:

Robotic Automation: Utilizes robots programmed to perform tasks, ranging from simple assembly to complex manufacturing processes.

Fixed Automation: Involves specialized equipment designed for specific tasks, common in high-volume production lines.

Programmable Automation: Employs computer-controlled machines capable of task reprogramming, ideal for versatile manufacturing needs.

Flexible Automation: Combines fixed and programmable automation for quick reconfiguration to accommodate various tasks.

Integrated Automation: Comprehensive systems amalgamating different automation types to optimize production, prevalent in precision-demanding industries.

Artificial Intelligence (A.I.) Automation: Utilizes advanced algorithms and machine learning to optimize processes, although still in early development stages.

The benefits of industrial automation are manifold, contributing to heightened productivity, enhanced quality control, improved workplace safety, and reduced

costs:

Increased Productivity: Automation accelerates production rates, ensures consistency, and operates 24/7, bolstering output and competitiveness.

Improved Quality Control: Automation facilitates meticulous monitoring and control of the production process, ensuring consistent product quality and

bolstering brand reputation and customer loyalty.

Enhanced Workplace Safety: By automating hazardous or physically demanding tasks, automation minimizes the risk of workplace injuries, safeguarding worker well-being and reducing legal liabilities.

Cost Reduction: Despite initial investment expenses, automation yields long-term benefits such as reduced labor costs, optimized resource utilization, and

decreased waste generation, enhancing profitability and sustainability.

In conclusion, industrial automation technology is indispensable in modern manufacturing, fostering efficiency, safety, and cost-effectiveness.

As technology evolves, automation's prevalence will continue to grow, enabling businesses to capitalize on its myriad benefits.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

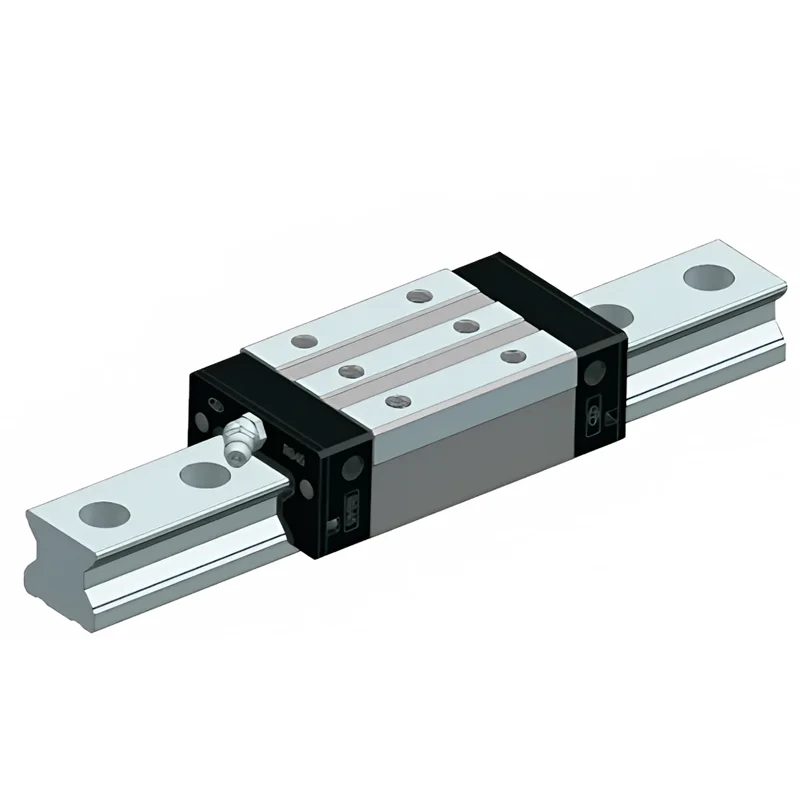

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS