Understanding the importance of bearing clearance

1.Bearing clearance, also known as the gap, refers to the amount of radial or axial movement of

the fixed side of the bearing's inner or outer ring when the other side is not fixed.

It can be categorized into radial clearance and axial clearance based on the direction of movement.

2.Running clearance, also known as working clearance, affects the rolling fatigue life,

temperature rise, noise, vibration, and other performance characteristics of the bearing.

3.The measurement of bearing clearance requires the application

of a specified measurement load to obtain stable measurement values.

Therefore, the measured clearance value (referred to as theoretical clearance) is significant as

it includes the additional elastic deformation caused by the measurement load.

However, for roller bearings, the elastic deformation is usually negligible.

4.The internal clearance of the bearing generally indicates the theoretical clearance before installation.

5."Installation clearance" refers to the clearance obtained by subtracting the interference

generated by the bearing's expansion or contraction due to being

installed in the shaft or housing from the theoretical clearance.

The "effective clearance" includes the dimensional change caused

by the bearing's internal temperature difference, added or subtracted from the installation clearance.

6.During bearing installation, there is a specific mechanical load placed clearance,

known as the "working clearance," which combines the adequate

clearance with the elastic deformation generated by the bearing load.

7.When the working clearance has a slightly negative value, the bearing fatigue life is maximized.

However, as the negative clearance increases, the fatigue life significantly decreases.

Therefore, for bearing clearance selection,

it is generally recommended to have a zero or slightly positive working clearance.

In certain cases, such as when improving bearing rigidity or reducing noise,

a further negative working clearance may be required.

Similarly, in cases of intense bearing temperature rise, a further positive working clearance might be necessary.

Specific analysis should be conducted based on the specific conditions.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

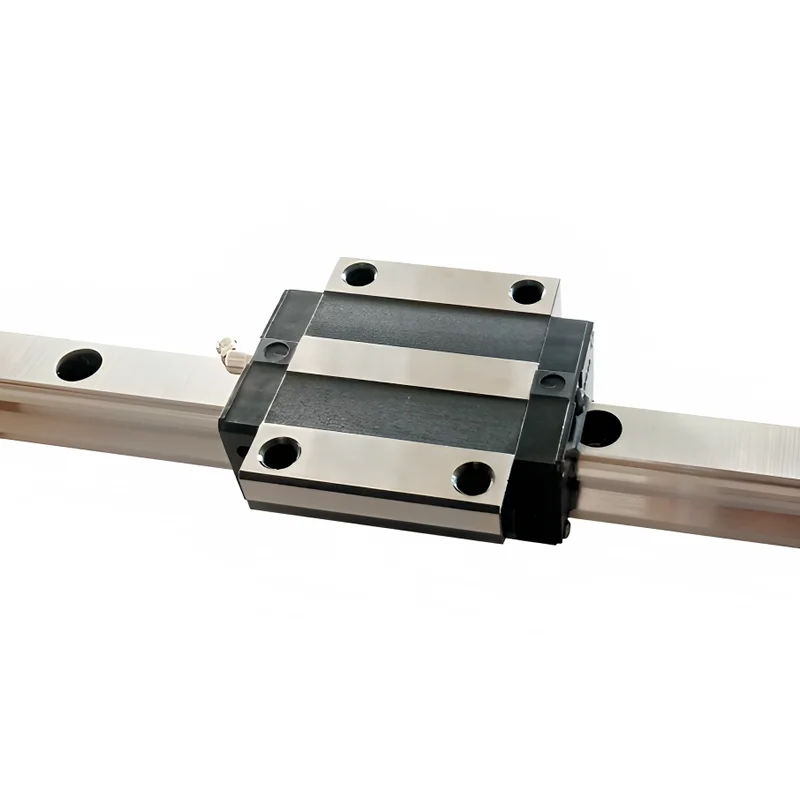

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

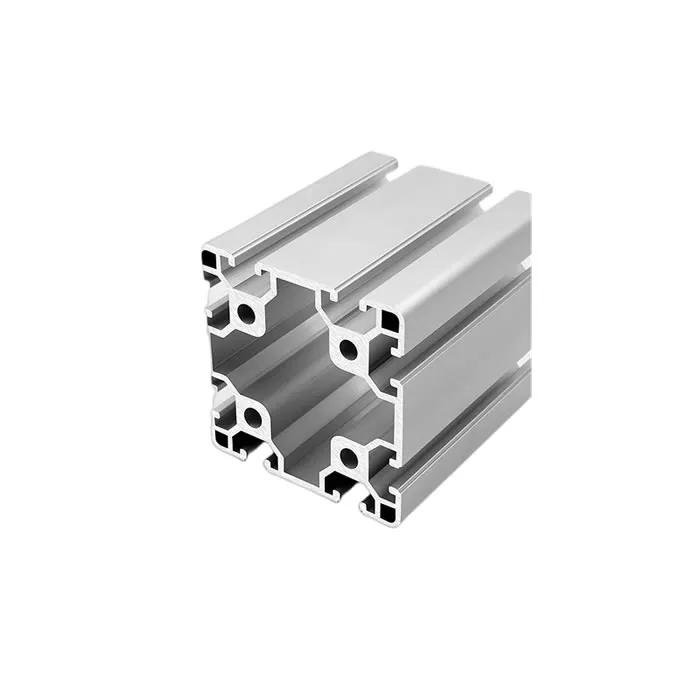

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd