Precautions for installation of linear bearings

SAIVS

Aug 28,2023

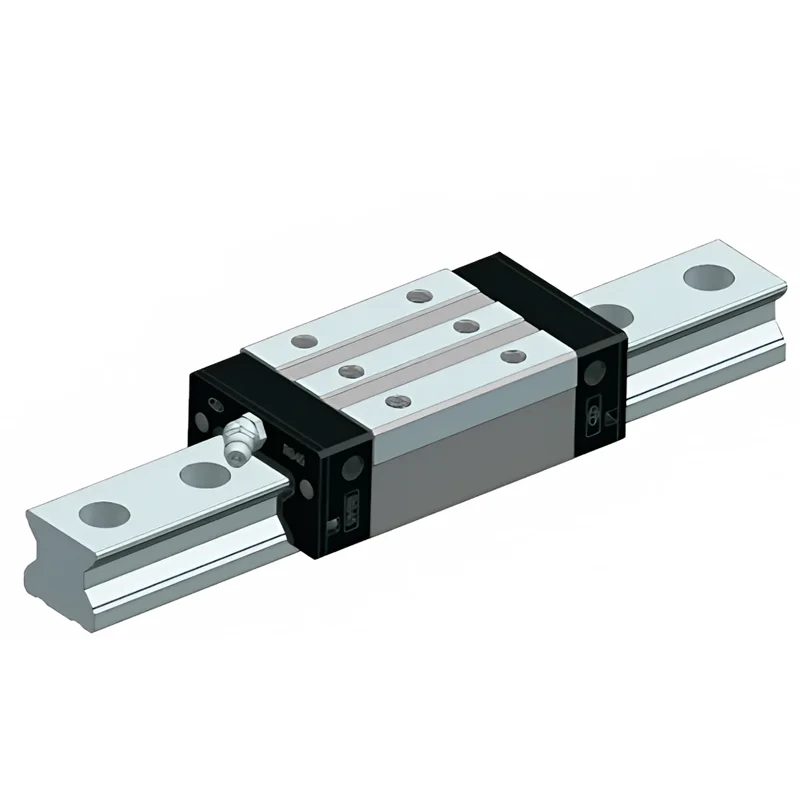

When installing the Linear Bearing into the bearing seat,

auxiliary tools should be used to avoid direct impact on the end face or sealing ring.

The shaft should be evenly guided in, and a buffer plate should be used to gently tap and install.

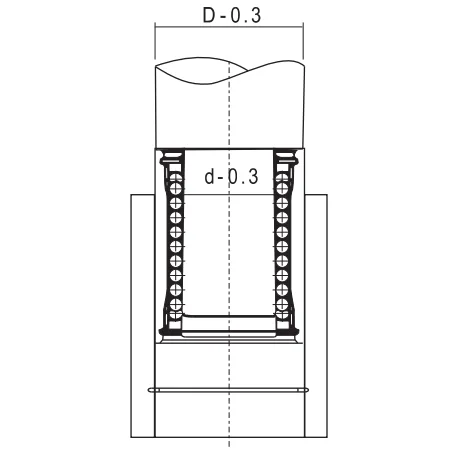

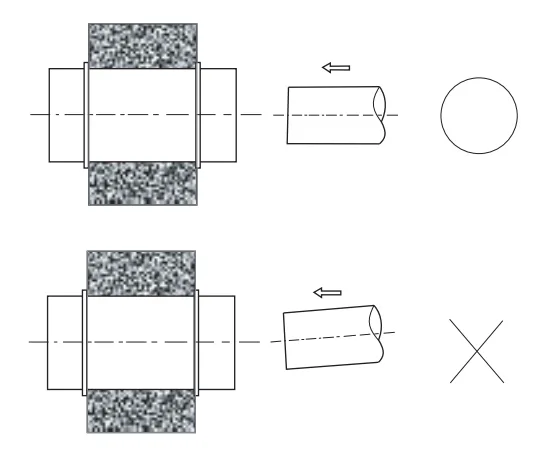

To thread the optical axis into a straight axis, the centerline of the shaft and bearing must be aligned.

If the shaft is tilted and inserted, the ball may fall off or cause deformation of the cage,

causing damage to the linear shaft record.

The applied load should be evenly distributed across the entire bearing,

especially when recording instantaneous loads, two or more bearings should be used.

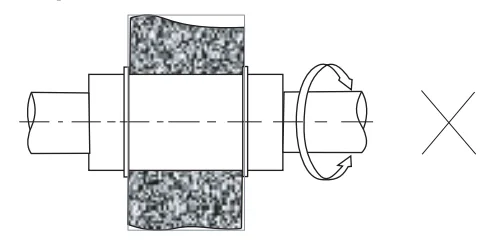

Linear bearings are not allowed to bear rotating loads, otherwise it may cause accidents.

Recommend Posts

Read More >>

How to avoid roller bearing failures

How to avoid roller bearing failures

Jan 21,2026

Premature roller bearing failure can occur due to various factors, including inadequate lubrication,...

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Apr 25,2025

In the fast-evolving world of industrial automation, precision and efficiency ar

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

Apr 03,2025

Enhance Your CNC Precision with SAIVS Linear Motion Ball Slide UnitsIn the rapidly advancing world o...

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Mar 20,2025

T - Slot Aluminum Extrusion Profile: The Ideal Choice for Your ProjectsIn the world of industrial ...