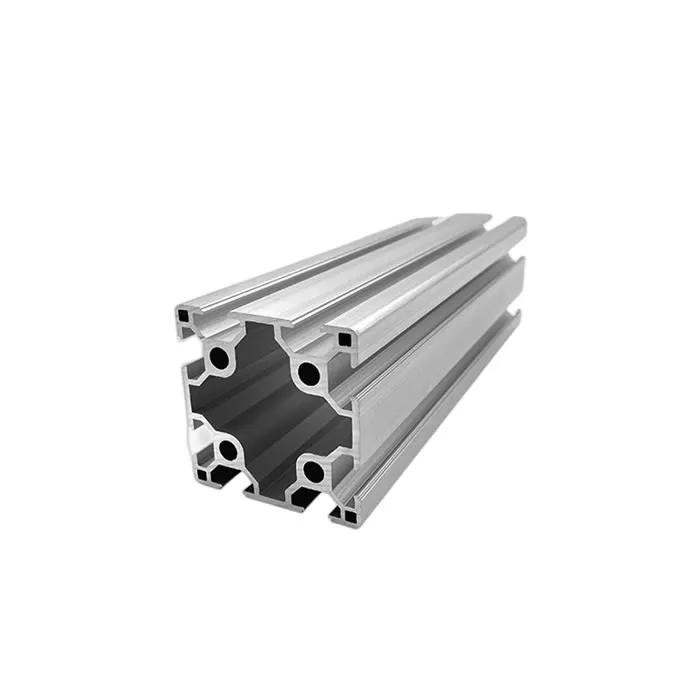

Key issues and solutions for manufacturing high-quality industrial aluminum profiles

When it comes to processing industrial aluminum profiles,

there are several problems that manufacturers should be aware of in order to produce high-quality products.

Improper Cutting

One of the most common problems in processing industrial aluminum profiles is improper cutting.

If the cutting is not performed correctly, it could lead to uneven edges, burrs, or even damaged material.

To avoid this, it's important to use the right cutting tools and techniques

and to ensure that your cutting machine is properly maintained.

Inconsistent Bending

Another common problem is inconsistent bending.

When bending aluminum profiles, it's important to use the right bending tools and techniques

and to pay close attention to the material's thickness and hardness.

If the aluminum is bent incorrectly, it can lead to deformation or even cracking.

Insufficient Surface Treatment

Industrial aluminum profiles are often used in environments where they are exposed to harsh conditions,

such as high temperatures or corrosive substances.

To ensure that the profiles can withstand these conditions,

it's important to treat the surface of the material with the right coating or anodizing process.

Otherwise, it could lead to corrosion or discoloration.

Poor Welding

Welding is an important step in processing industrial aluminum profiles,

and poor welding can lead to weak or poorly-fused joints.

To avoid this, it's important to use the right welding techniques and equipment

and to ensure that the welding area is clean and free of debris.

In conclusion, by avoiding the common problems discussed above,

manufacturers can produce high-quality industrial aluminum profiles that meet the requirements of their customers.

It's important to use the right tools and techniques, pay attention to the details,

and properly maintain production equipment to ensure a smooth and successful production process.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS