How Many Bearings Does a Hydraulic Excavator Have

Hydraulic excavators are complex machines with many moving parts. Bearings are an essential part of these machines,

as they provide support and allow the parts to move smoothly. The number of bearings on a hydraulic excavator varies

depending on the size and type of excavator. However, a typical hydraulic excavator will have between 100 and 200 bearings.

The most common types of bearings found on hydraulic excavators are:

Ball bearings are used to support rotating shafts. They are typically made of steel or stainless steel and have a

series of small balls that roll between the inner and outer races.

Ball bearings on a hydraulic excavator

Roller bearings are also used to support rotating shafts. They are typically made of steel or stainless steel

and have a series of small rollers that roll between the inner and outer races.

Roller bearings on a hydraulic excavator

Thrust bearings are used to support axial loads. They are typically made of steel or stainless steel and have

a series of small rollers that roll between the inner and outer races.

Thrust bearings on a hydraulic excavator

Tapered roller bearings are used to support heavy loads. They are typically made of steel or stainless steel

and have a series of tapered rollers that roll between the inner and outer races.

Tapered roller bearings on a hydraulic excavator

Bearings are an essential part of hydraulic excavators. They help to ensure that the machines operate smoothly and efficiently.

Proper maintenance of bearings is important to extend their lifespan and prevent damage to the excavator.

Here are some tips for maintaining bearings on hydraulic excavators:

Inspect the bearings regularly for signs of wear or damage. This includes looking for cracks,

dents, or excessive wear on the surfaces of the bearings.

Lubricate the bearings regularly. The type of lubricant used will depend on the type of bearing.

Replace worn or damaged bearings as soon as possible. Worn or damaged bearings can lead to premature failure of the excavator.

By following these tips, you can help keep the bearings on your hydraulic excavator in good condition and extend their lifespan.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

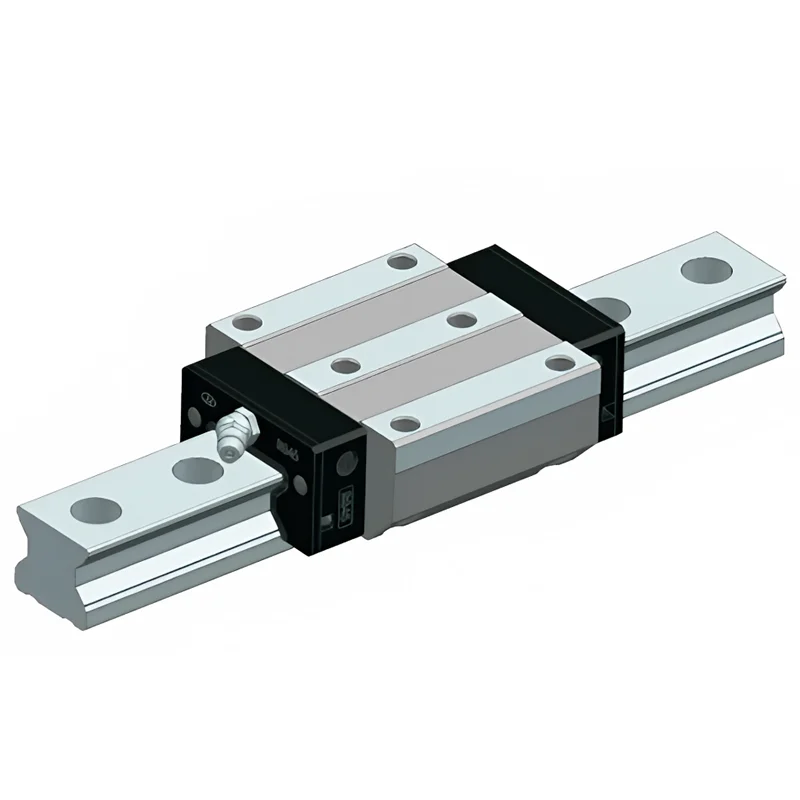

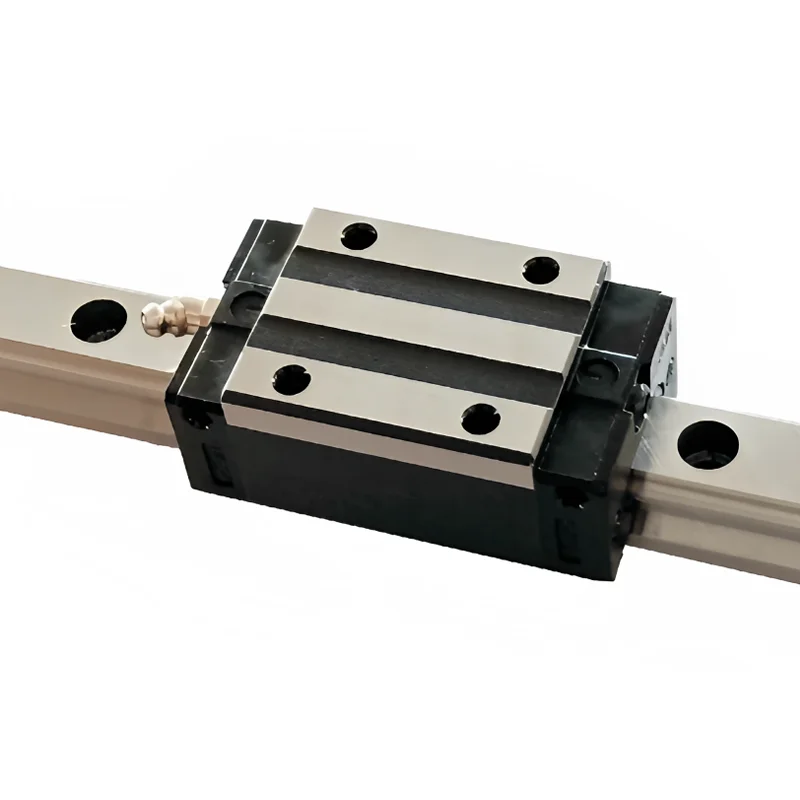

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS