Essential Accessories for Assembling Aluminum Framework

Introduction

Aluminum frameworks are widely used in various industries due to their lightweight, corrosion resistance, and versatility. Whether it's constructing industrial structures, assembling exhibition booths, or creating ergonomic workstations, aluminum frameworks offer a flexible solution. However, to ensure a seamless assembly process and structural integrity, it's essential to have the right accessories on hand. In this article, we'll explore the key accessories needed for assembling aluminum frameworks.

Fasteners:

Fasteners play a crucial role in joining aluminum extrusions together securely. Common fasteners used in aluminum framework assembly include T-slot nuts, bolts, screws, and washers. T-slot nuts are specifically designed to fit into the slots of aluminum extrusions, providing a convenient and adjustable connection point for other components.

Corner Brackets:

Corner brackets are essential for creating strong and stable joints at corners and intersections of aluminum framework structures. These brackets come in various shapes and sizes, such as L-shaped brackets, T-shaped brackets, and 3-way corner brackets, allowing for flexibility in design and construction.

End Caps and Covers:

End caps and covers serve both functional and aesthetic purposes in aluminum framework assembly. They provide a finished look to the exposed ends of aluminum extrusions while also protecting against dust, debris, and sharp edges. Additionally, end caps with integrated features such as hinges or handles can enhance accessibility and usability of the framework.

Joining Plates and Gussets:

In situations where additional reinforcement is needed, joining plates and gussets are used to strengthen connections between aluminum extrusions. These plates are typically made from aluminum or steel and are secured to the extrusions using bolts or rivets. By distributing loads more evenly, joining plates and gussets help improve the overall stability and load-bearing capacity of the framework.

Panel Mounting Accessories:

For applications requiring the attachment of panels, shelves, or other flat surfaces to the aluminum framework, panel mounting accessories are indispensable. These accessories may include panel clips, brackets, and hinges designed to securely hold panels in place while allowing for easy installation and removal as needed.

Leveling Feet and Casters:

To ensure proper alignment and mobility of assembled aluminum frameworks, leveling feet and casters are essential accessories. Leveling feet can be adjusted to compensate for uneven surfaces, while casters provide mobility for frameworks that need to be moved or repositioned frequently. Both accessories contribute to the stability and usability of the framework in various environments.

Conclusion

Assembling aluminum frameworks requires careful consideration of the necessary accessories to ensure structural integrity, functionality, and aesthetics. By utilizing the right combination of fasteners, brackets, end caps, joining plates, panel mounting accessories, and leveling feet or casters, builders and designers can create durable and versatile aluminum structures tailored to their specific needs and applications.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

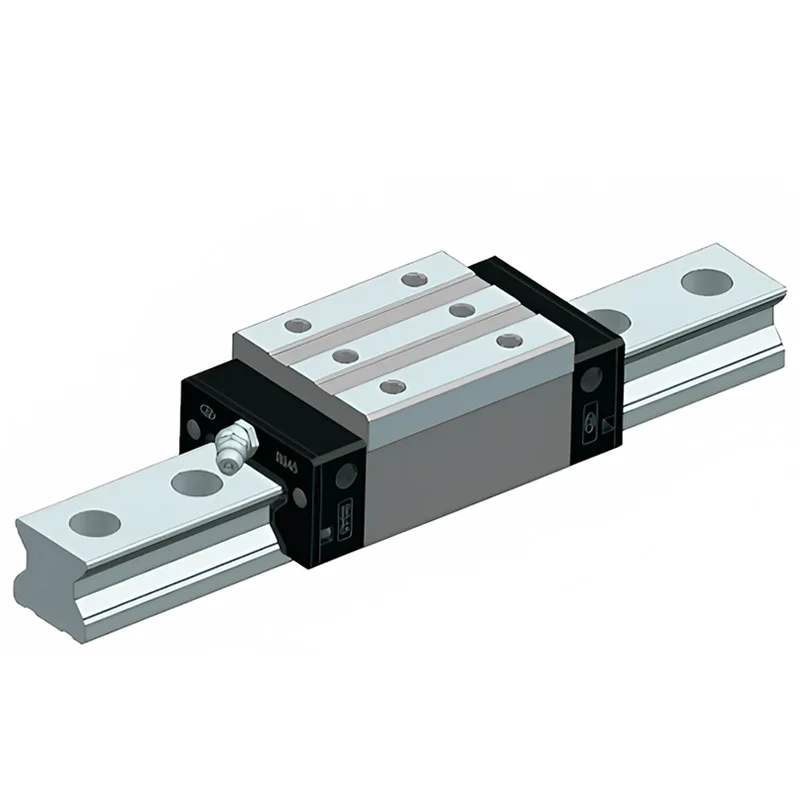

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS