T Nuts: Versatile Fasteners for Flush Finishes

T nuts, also known as tee nuts or blind nuts, offer a unique solution for fastening objects to wood, plastic, and metal. They excel in situations where a smooth, flush finish is desired, making them ideal for furniture, signage, and various other applications.

Types of T Nuts

There are four main types of T nuts, each suited for specific needs:

Pronged T Nuts: The most common type, featuring three prongs that spread apart when inserted into a pre-drilled hole, creating a secure hold in wood, plastic, or even metal.

Drop-in T Nuts: Perfect for limited access scenarios, these simply insert and lock into a pre-existing T-slot. They are commonly made from steel or stainless steel and come in various sizes.

Roll-in T Nuts: Designed for a flush finish, these roll into a T-slot for a clean look. Typically made from aluminum or brass, they too offer various size options.

Threaded T Nuts: For applications demanding high holding power, threaded T nuts provide a screw-in solution for increased grip. These are generally made from steel or stainless steel and come in various sizes.

Common Applications of T Nuts

Furniture: T nuts are a popular choice for assembling furniture, discreetly fastening components like shelves and drawers due to their flush finish.

Signage: Their strong hold makes them perfect for securing letters and numbers onto signage panels, ensuring they stay put.

Industrial Applications: T nuts are frequently used in industrial settings to fasten fixtures, tools, and equipment due to their reliable holding power.

Machinery: The clean finish of T nuts allows them to be hidden from view while effectively securing components within machinery.

Installing T Nuts

The installation process is straightforward and requires just a drill, screwdriver, and a pre-drilled hole sized for your specific T nut. Here's a step-by-step guide:

Measure and Mark: Use a pencil to mark the exact location for the T nut on the material.

Drill the Hole: Drill a hole according to the size requirement of your chosen T nut.

Insert the T Nut: Push the T nut fully into the drilled hole.

Secure the T Nut: For pronged T nuts, gently tap the prongs with a hammer to secure them. For threaded T nuts, simply screw them in using a screwdriver.

With their versatility and ease of use, T nuts offer a valuable solution for various fastening applications, particularly when a clean and secure finish is essential.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

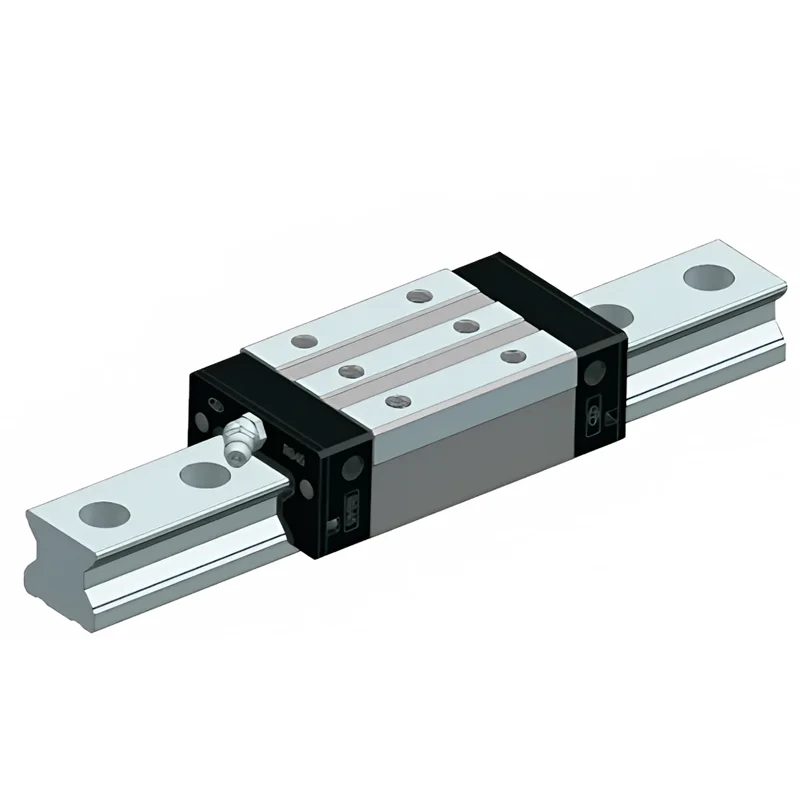

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

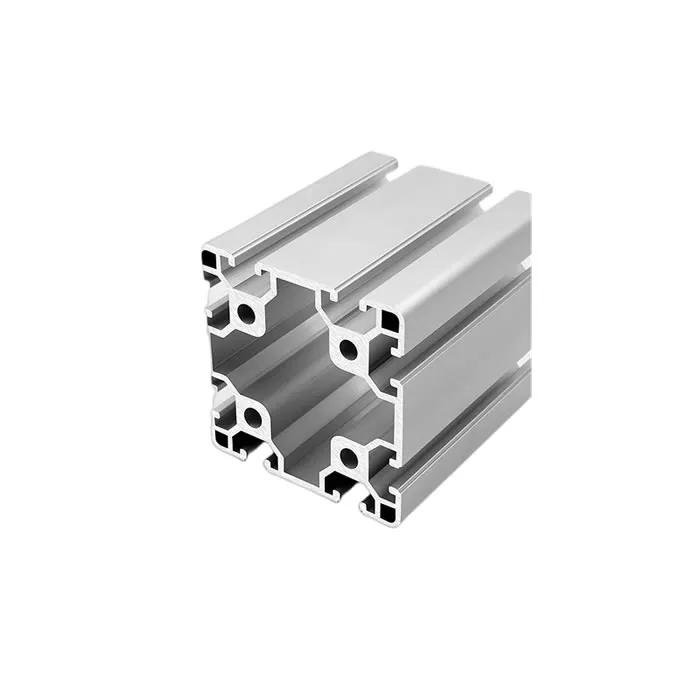

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS