5 Things to Consider When Choosing Industrial Wheels

Industrial wheels play a crucial role in various material handling applications, such as hand trucks,

carts, and mobile shelving units. They provide the ability to easily move objects and materials.

However, when purchasing industrial wheels for your business, there are several factors to consider.

1) Bearing Type

The bearing type is an important consideration when choosing industrial wheels. Bearings connect the wheels to the axles.

There are two common types: plain bearings and roller bearings.

Plain bearings are simple, inexpensive, and low-maintenance.

Roller bearings consist of metal rollers housed within a casing.

2) Wheel Material

The wheel material is another crucial factor to think about. Industrial wheels come in different materials,

including metals/alloys and synthetic materials. Common options include cast iron, drop-forged steel,

ductile iron, nylon, phenolic, poly/aluminum composite, poly/cast iron composite,

rubber, rubber/aluminum composite, and rubber/cast iron composite.

3) Wheel Diameter

Industrial wheels are available in various sizes with different diameters.

The wheel diameter directly affects how easily it rolls. Generally speaking,

larger industrial wheels require less force to roll compared to smaller ones.

If you intend to install the wheels on the bottom of an object that will be pushed around,

choosing larger diameter wheels can provide easier movement.

4) Load Rating

The load rating is a critical consideration when selecting industrial wheels.

It represents the maximum weight that an individual wheel can support safely.

Smaller industrial wheels may have load ratings around 300-400 pounds while

heavier-duty ones can handle loads up to 2-4 thousand pounds or more.

It's important to note that load ratings are per individual wheel.

If you're installing multiple industrial wheels on an object (e.g., four),

you can multiply the load rating by the number of installed

wheels to determine the maximum weight capacity.

5) Tread Width

Tread width should also be taken into account when choosing industrial wheels since they

are commonly used in work-related applications where traction is essential.

Tread width refers to the width of the wheel's tread surface that comes into

contact with the ground or surface being rolled on. Along with wheel diameter

considerations mentioned earlier; tread width helps determine overall

size and performance characteristics of industrial wheels.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

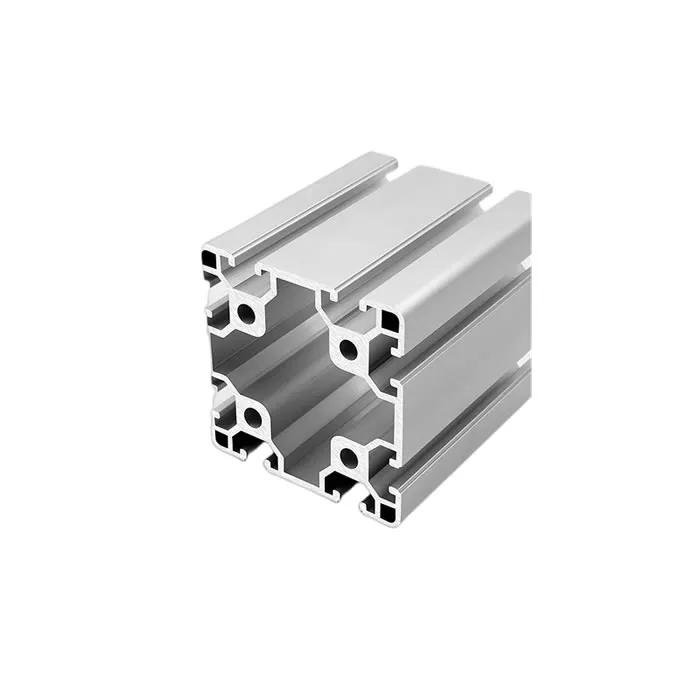

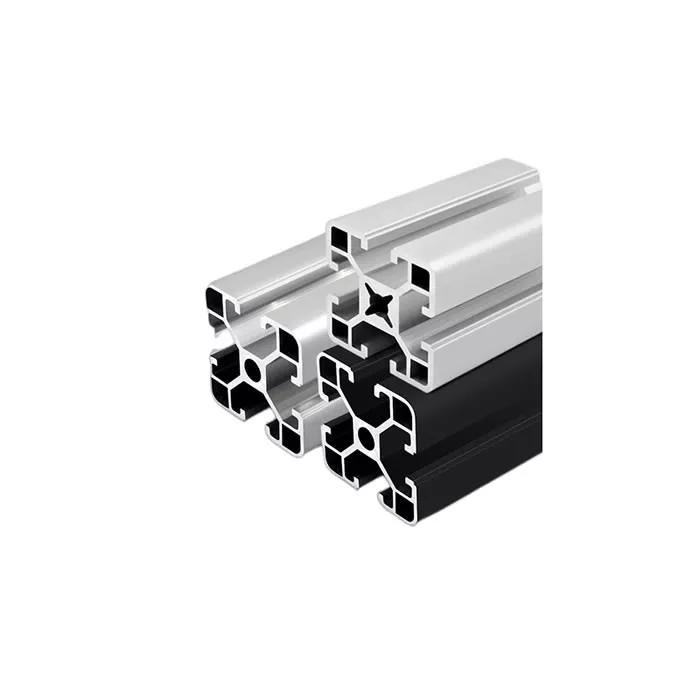

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS