Ball Screw or Screw: Which One to Choose

How does a screw work?

A screw is a crucial component that utilizes a simple yet effective mechanical principle.

By rotating a steel or metal rod in the shape of a helix, screws transmit motion.

Screws are used to efficiently transfer force and find wide applications in various fields.

Understanding how screws work will help in understanding the differences between a Ball Screw and a regular screw.

How does a ball screw work?

A ball screw is an improved version of a screw, particularly used in fields that require precise motion control.

It consists of a screw and a ball nut, which is filled with small steel balls.

These steel balls move along with the screw, providing efficient motion transfer and high precision.

Ball screws are especially useful in areas that demand high rotational speed and accurate position control.

Why Choose A Ball Screw Or Lead Screw?

Ball screws and lead screws are both types of mechanical actuator, and each type

has its own advantages and disadvantages. On the face of it, lead screws are just cheaper.

However, choosing the right type of screw to use in your application is a lot more complicated than that.

Advantages Of Ball Screws

-Less Friction

-Require Less Torque

-Generate Less Heat

-Greater Efficiency

-Longer Lifespan

Disadvantages Of Ball Screws

-More Expensive

-Generate More Noise

-Can Be Problematic In Vertical Applications

-Require Braking Systems To Avoid Back-Driving

-Require Lubrication To Attain Design Life

Advantages Of Lead Screws

-Cost Less

-Self-Locking, Need No Braking System

-Better For Vertical Applications

-DISADVANTAGES OF LEAD SCREWS

-Generate More Friction

-Generate More Heat

-Slower

-Shorter Lifespan

How to determine: Ball screw or screw?

Ball screws and screws each have their own advantages and disadvantages, and the choice depends

on the intended purpose and specific requirements. Regular screws have a relatively simple structure,

lower manufacturing costs, and easier maintenance. However, for applications requiring precise position

control and high speed, choosing a ball screw is recommended. Ball screws offer high precision control,

efficient motion transfer, and are widely used in fields that require accurate positioning and repeatability.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

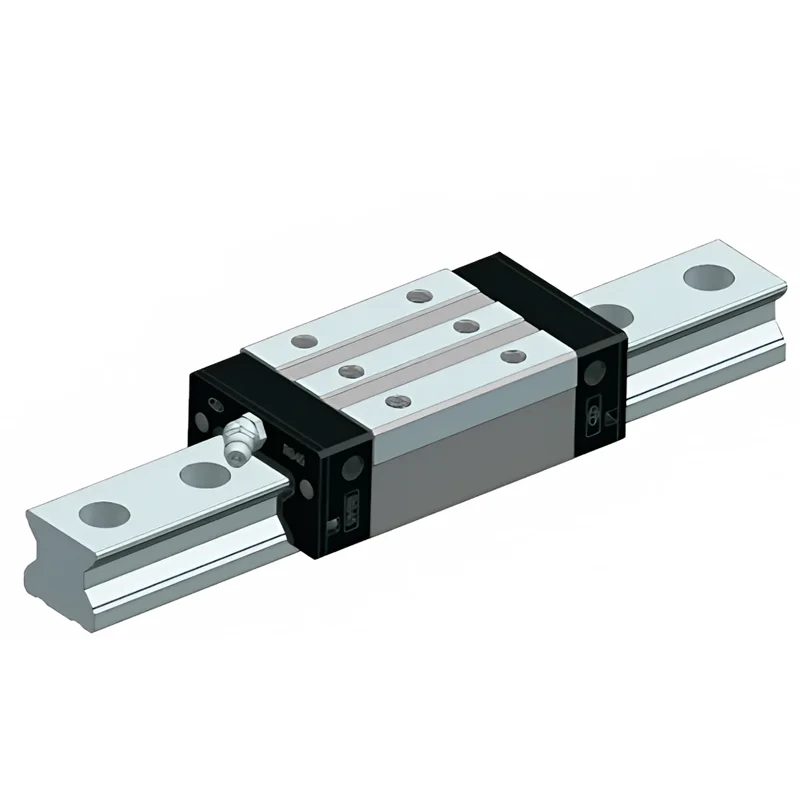

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

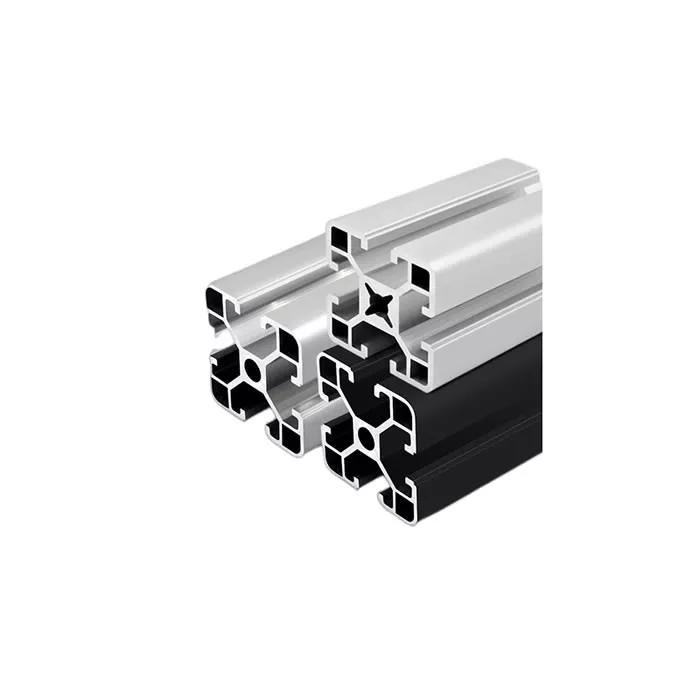

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS