Performance Of Radial Bearings

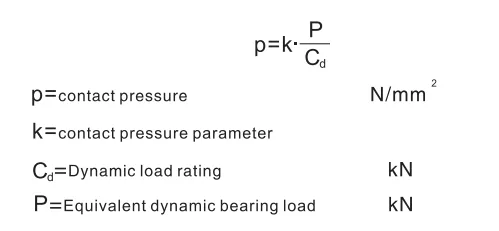

| Contact surface combination | Value of load ratioCd/P |

| Steel/steel | 2 |

| Steel/bronze | 2 |

| Steel/PTFE fabric | 1.75 |

| Steel/PTFE composite material | 2 |

| Steel/copper alloy | 2 |

| Contact surface combination | Load factor k |

| Steel/steel | 100 |

| Steel/bronze | 50 |

| Steel/PTFE fabric | 150 |

| Steel/PTFE composite material | 100 |

| Steel/copper alloy | 100 |

Bearing internal clearance

Bearing internal clearance is defined as the total distance throughwhich one ring

can be moved radially(radial internal clearance)oraxially(axial internal clearance)

in relation to the other ring under adefined measuring load.

It is necessary to distinguish between the internal clearance of abearing before

it is mounted and the internal clearance of a mountedbearing when in operation(operational clearance).

The initial clearancewill always be greater than the operational clearance

because the ringsare expanded or compressed by interferences fits and

as a result of thedifferences in thermal expansion of the bearing rings and matingcomponents.

The bearing internal clearance referred to as normal has been selected sothat

when bearings a suitable operarional clearance will be obtained.

Forother conditions, e.g where both rings are mounted

with an interference fitorwhere unusual temperatures prevail,

bearings with greater or smallerinternal clearance than normal may be required.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

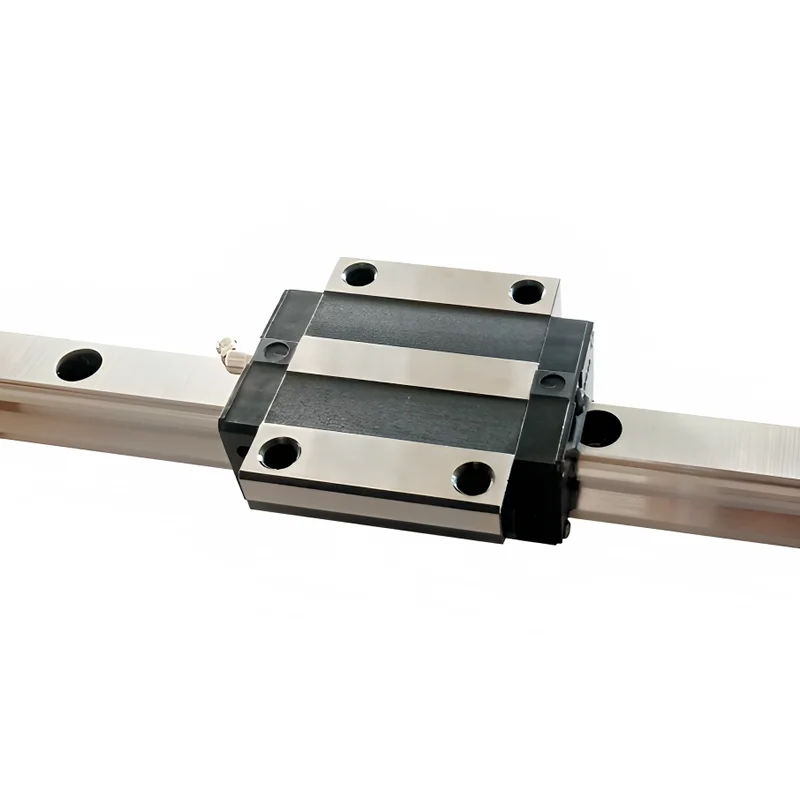

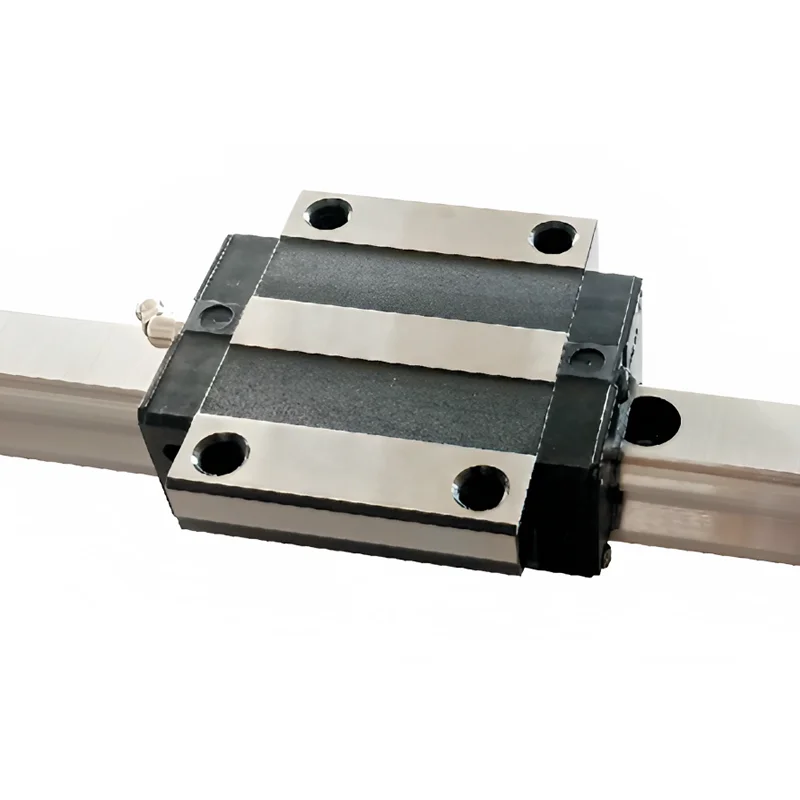

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS