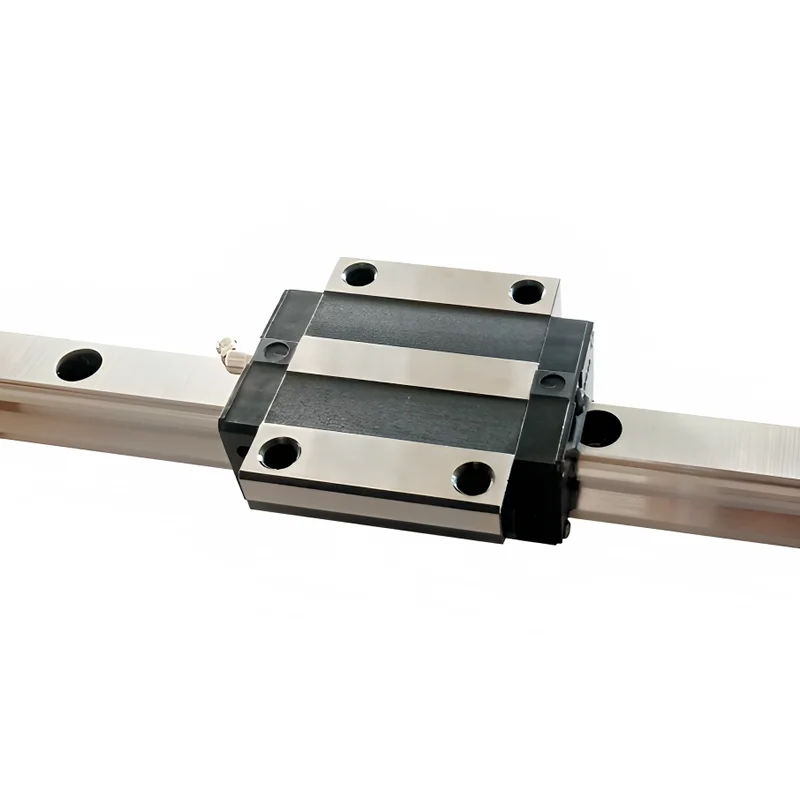

Installation of Linear Guideways

Three installation methods are recommended based on the required running accuracy and the degreeof impacts and vibrations.

(1)Mounting methods

It is possible that the rails and the blocks will be displaced when the machine is subjected to vibrationsand impacts.

To eliminate these difficulties and achieve high running accuracy.

(2)Procedure of rail installation

1.Before starting, remove all dirt from the mounting surface of the machine.

This is crucial to ensure proper adhesion and prevent any interference during the installation process.

Clear away any debris, oil, or dust using a clean cloth or brush.

Make sure the surface is clean and smooth for optimal performance.

2.Place the linear guideway gently on the bed and align it with precision.

Take care not to drop or mishandle the guideway to avoid any damage.

It is essential to bring the guideway into close contact with the datum plane of the bed for accurate positioning and alignment.

Ensure that there are no gaps or misalignments between the guideway and the bed.

3.Check for correct thread engagement when inserting a bolt into the mounting hole

while the rail is being placed on the mounting surface of the bed.

Ensuring proper thread engagement guarantees a secure and stable connection.

Carefully thread the bolts into the mounting holes without overtightening or cross-threading.

If there are any issues with the thread engagement, rectify them before proceeding further.

4.Tighten the push screws sequentially to ensure close contact between the rail and the side datum plane.

Push screws play a vital role in maintaining the alignment and stability of the linear guideway.

Start by tightening the screws closest to the initial contact point between the rail and the datum plane.

Gradually work your way along the rail, ensuring each screw is tightened evenly and securely.

5.Tighten the mounting bolts with a torque wrench to the specified torque.

Proper bolt tightening is crucial for the overall stability and performance of the linear guideway system.

Refer to the manufacturer's guidelines or specifications to determine the appropriate torque value.

Use a torque wrench to apply the specified torque evenly to each mounting bolt.

This ensures uniform pressure distribution and eliminates the risk of over-tightening or under-tightening.

6.Install the remaining linear guideway in the same way as described above.

Repeat the steps for each additional guideway, maintaining consistency and attention to detail throughout the process.

Remember to clean the mounting surfaces, align the guideways accurately,

check thread engagement, tighten push screws, and secure the mounting bolts with the specified torque.

By following these steps meticulously, you can ensure a proper and reliable installation of the linear guideway system.

(3)Procedure of block instal

Place the table gently on the blocks. Next, tightenthe block mount ng bolts temporarily.

Push the blocks against the datum plane of thetable and position the table by tightening the pushscrews.

The table can be fixed uniformly by tightening the mounting bolts on master guide side and subsidiary side in 1 to 4 sequences.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS