Installation and lubrication of joint bearings

Install

When assembling the joint bearing series, the position of the outer ring dividing surface is very important.

To avoid direct load on the dividing surface, the dividing surface should be perpendicular to the direction of the load.

This can effectively disperse and reduce the impact of load on the segmentation surface,

avoiding premature wear and damage to the segmentation surface.

During the assembly process, it is necessary to carefully adjust and confirm the vertical relationship between

the dividing surface and the load direction to ensure its complete verticality,

in order to ensure the stability and reliability of the joint bearing.

Special attention should be paid to maintaining a right angle between the dividing surface and the corresponding direction,

which is an important step in the assembly process of joint bearings and can improve the service life and work efficiency of the bearings.

Lubrication

Oil type joint bearings can operate without lubrication when the load is applied and the swing speed is low.

However, in order to ensure its performance and lifespan, it is generally necessary to regularly replenish grease.

During the initial installation and operation, it is recommended to moderately shorten

the lubrication cycle to strengthen the lubrication and protection of the bearings.

For non oil fed joint bearings, adding lithium soap based grease before operation can further extend the service life of the bearing.

In addition, injecting grease can effectively prevent dust and foreign objects from entering the surrounding space of the bearing,

and maintain the good working condition of the bearing. Therefore, when using oil-free joint bearings,

attention should be paid to the maintenance and upkeep of the bearings,

and lubricating grease should be reasonably applied to ensure their stability, reliability, and service life.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

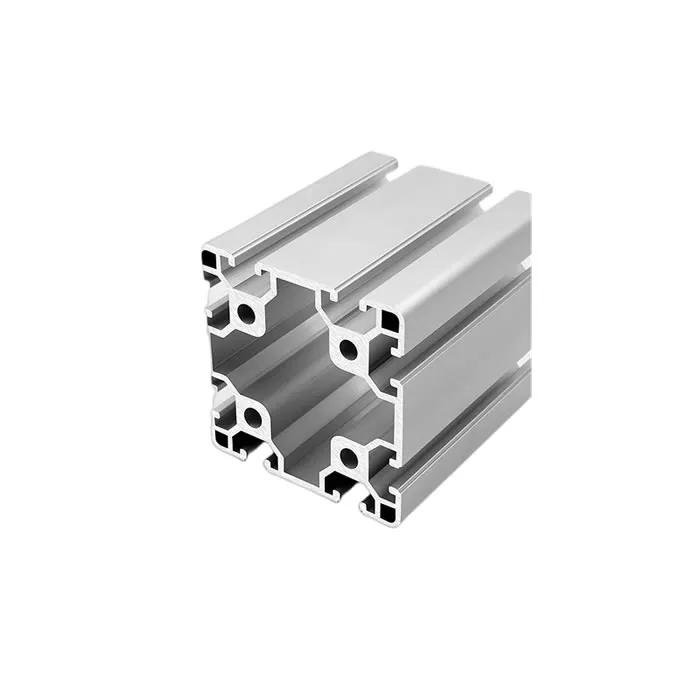

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS