How to measure a socket head cap screw

Understanding the dimensions of your socket head cap screw is crucial for finding a perfect replacement or ensuring proper fit in your project. Here's a comprehensive guide to measuring the key features:

Screw Diameter (Major Diameter):

This refers to the widest part of the screw's threaded section.

Use a caliper for the most accurate measurement. If a caliper isn't available, a ruler can work in a pinch.

Place the jaws of the caliper (or the edge of the ruler) on opposite sides of the threads and squeeze the jaws (or hold the ruler steady) to obtain the reading.

Thread Pitch:

This specifies the distance between neighboring threads along the screw shaft.

There are two common ways to measure thread pitch:

Threads per Inch (TPI): Hold a ruler or a thread pitch gauge (a tool specifically designed for this purpose) against the threads. Count the exact number of threads that fall within one inch length of the screw shaft. This value represents the TPI.

Distance Between Threads: Alternatively, position the ruler or thread pitch gauge along the threads. Measure the distance from the peak of one thread to the peak of the next. This distance represents the thread pitch in millimeters or inches (depending on your measuring tool).

Screw Length:

This is the overall length of the screw, excluding the head.

Use a ruler or tape measure to determine the distance from the flat underside of the head (where the head meets the shank) to the tip of the screw.

Drive Size (Socket Size):

Socket head cap screws have a hexagonal recess in the head for driving them with a wrench or socket driver.

Measure the distance across opposite flats (parallel sides) of the hexagon using a caliper. This value represents the socket size, commonly denoted in fractions of inches (e.g., 1/8", 5/32", 3/16").

*Tips:

Ensure your measuring tools are clean and accurate for precise readings.

When using a ruler, hold it flat against the screw for accurate measurements.

If you're unsure about any measurement, it's always better to err on the side of caution and get a slightly larger screw than a potentially undersized one.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

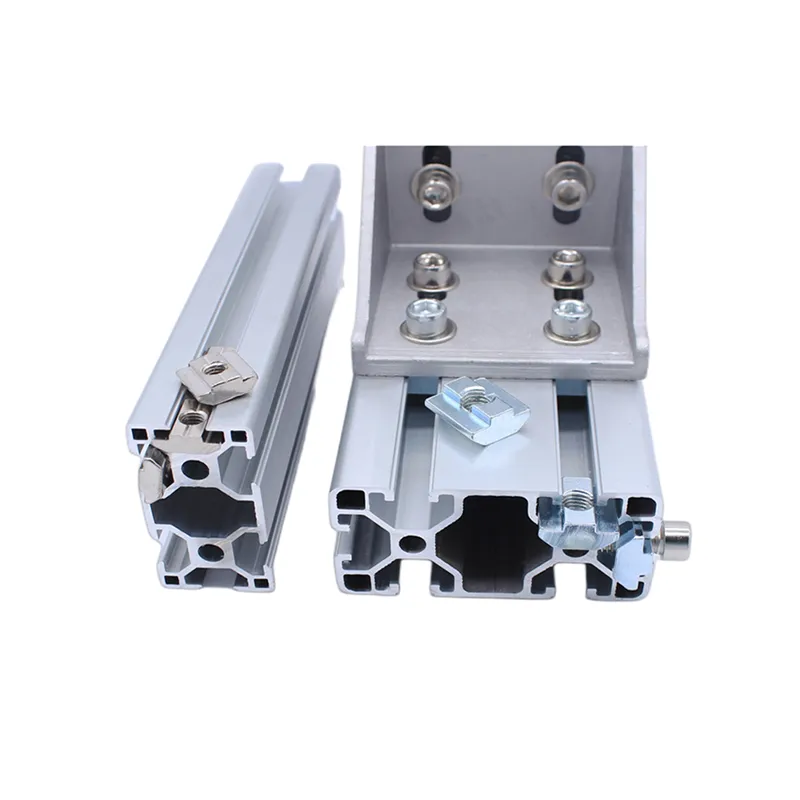

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS