How to join aluminium profiles

Joining aluminum profiles can be done in several ways, depending on your specific

needs and the tools and materials you have at your disposal.

Here are some common methods for joining aluminum profiles:

1. Mechanical Fastening:

- Bolts and Nuts: Using bolts and nuts is a straightforward way to join aluminum profiles.

You'll need pre-drilled holes for the bolts and a wrench to tighten the nuts.

- Rivets: Aluminum rivets are a popular choice for joining aluminum profiles.

You'll need a rivet gun and rivets of the appropriate size.

- Screws: Self-tapping screws or machine screws can be used to attach aluminum profiles.

Pre-drilling may be necessary for self-tapping screws.

2. Welding:

- TIG (Tungsten Inert Gas) Welding: TIG welding is a common method for joining aluminum profiles.

It offers precise control and clean welds, but it requires skill and specialized equipment.

- MIG (Metal Inert Gas) Welding: MIG welding is another option and is generally easier to learn than TIG welding.

It uses a consumable wire electrode and a shielding gas.

3. Adhesive Bonding:

- Structural Adhesives: Specialized adhesives designed for aluminum bonding can be used to join profiles.

Surface preparation is essential, and you'll need to allow time for the adhesive to cure.

4. Corner Brackets and Connectors:

- There are various corner brackets and connectors designed for aluminum profiles, such as T-slot extrusions.

These brackets and connectors often come with pre-drilled holes for easy assembly.

5. Slot Nuts and T-Bolts:

- For T-slot aluminum profiles, slot nuts and T-bolts can be used to create adjustable connections within the T-slot channels.

6. Clamps and Fasteners:

- Use clamps and fasteners designed for aluminum profiles to create temporary or adjustable connections.

7. Friction Stir Welding:

- Friction stir welding is a solid-state welding process suitable for aluminum.

It uses a rotating tool to soften and join the aluminum without melting it.

8. Brazing:

- Aluminum brazing involves heating the profiles and melting a filler material with a lower melting point to create a joint.

9. Interlocking Joints:

- Some aluminum profiles are designed with interlocking joints, allowing them to be assembled without the need for additional fasteners.

The choice of method depends on factors like the application, required strength, appearance, and available tools.

Keep in mind that some methods, like welding, may require safety precautions due to the use of heat and potentially hazardous fumes.

Additionally, consider the specific type of aluminum alloy you are working with,

as different alloys may require different joining techniques.

Always follow manufacturer recommendations and safety guidelines when working with aluminum profiles.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

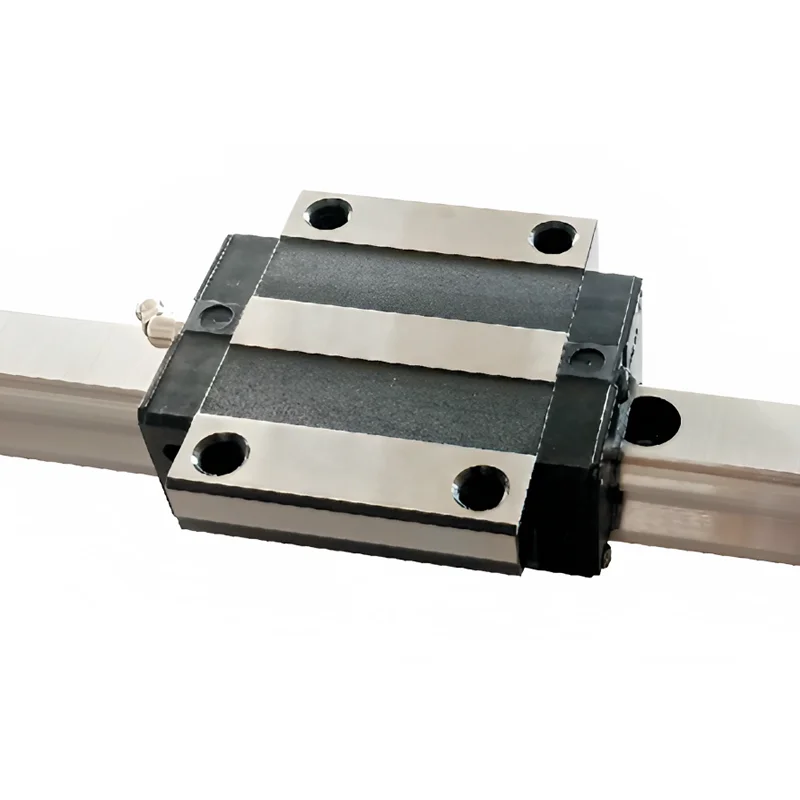

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd