How to Choose The Right Profile End Fasteners for Your Project

1. Understand Your Project Requirements

Material Type: Identify the materials you will be fastening (e.g., wood, metal, plastic).

Load and Stress: Determine the load-bearing requirements and the amount of stress the fasteners will endure.

Environmental Conditions: Consider exposure to elements like moisture, chemicals, and temperature variations.

2. Types of Fasteners

Bolts and Nuts: Suitable for high-strength applications and can be used with washers for added security.

Screws: Common for wood, metal, and plastic; available in various heads (flat, round, etc.) and drives (Phillips, slotted, etc.).

Rivets: Ideal for permanent fastening where access to both sides of the material is available.

Anchors: Used for securing fasteners into materials that are brittle or otherwise unable to hold threads.

Clips and Clamps: Used for holding objects together temporarily or permanently without damaging the materials.

3. Fastener Material

Steel: Strong and durable, suitable for most applications; can be prone to corrosion unless treated.

Stainless Steel: Offers excellent corrosion resistance, ideal for outdoor or corrosive environments.

Brass: Corrosion-resistant and conductive, often used in electrical applications.

Aluminum: Lightweight and corrosion-resistant, suitable for light to medium load applications.

Plastic: Used for lightweight applications with minimal load requirements.

4. Size and Length

Diameter: Ensure the diameter of the fastener matches the holes in the materials being joined.

Length: The length should be sufficient to penetrate both materials and provide adequate holding power without protruding excessively.

5. Thread Type

Coarse Threads: Provide better holding power in softer materials.

Fine Threads: Suitable for hard materials and where a more precise fit is needed.

6. Special Features

Self-Tapping Screws: Create their own thread as they are driven into materials.

Self-Drilling Screws: Feature a drill bit-like tip that drills its own pilot hole.

Locking Features: Some fasteners come with locking mechanisms to prevent loosening under vibration.

7. Standards and Grades

Standards: Ensure fasteners comply with industry standards such as ISO, ANSI, or DIN.

Grades: Higher-grade fasteners (e.g., Grade 8 bolts) offer greater strength and durability.

8. Aesthetic Considerations

Finish: Choose a finish that matches the aesthetic requirements of your project (e.g., zinc-plated, black oxide).

Head Style: Select a head style that complements the design (e.g., countersunk, round head).

9. Installation Tools

Compatibility: Ensure you have the necessary tools for installation, such as drills, wrenches, or screwdrivers.

Ease of Use: Some fasteners may require specialized tools or expertise for installation.

10. Cost and Availability

Budget: Consider the cost of the fasteners in relation to your budget.

Availability: Ensure the fasteners are readily available in the quantities needed for your project.

Conclusion

Selecting the right profile end fasteners involves careful consideration of the project requirements, materials, environmental conditions, and specific fastener characteristics. By evaluating these factors, you can choose the most appropriate fasteners that ensure durability, strength, and proper functionality for your project.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

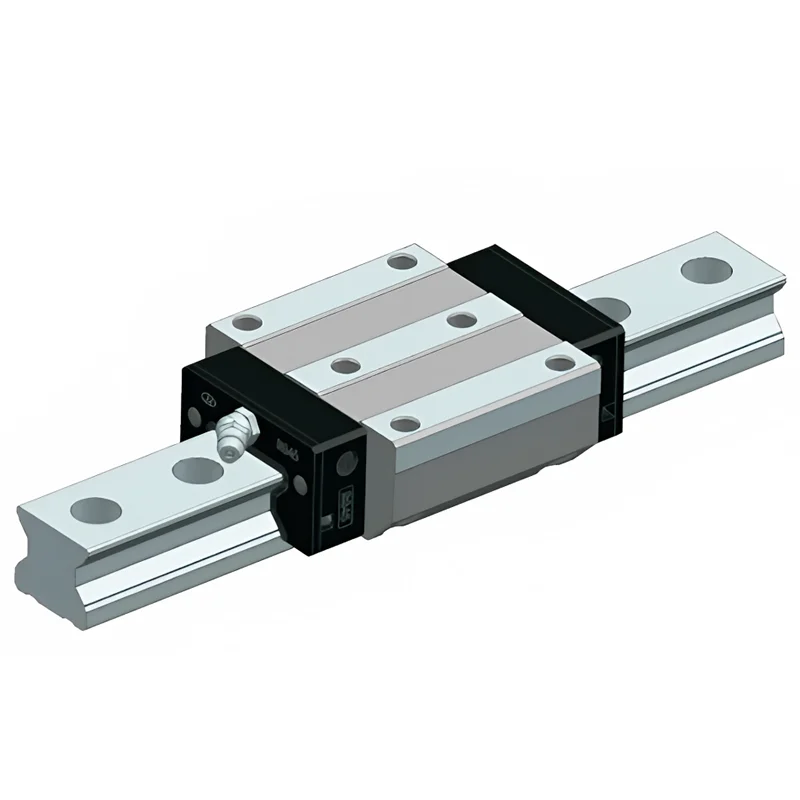

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

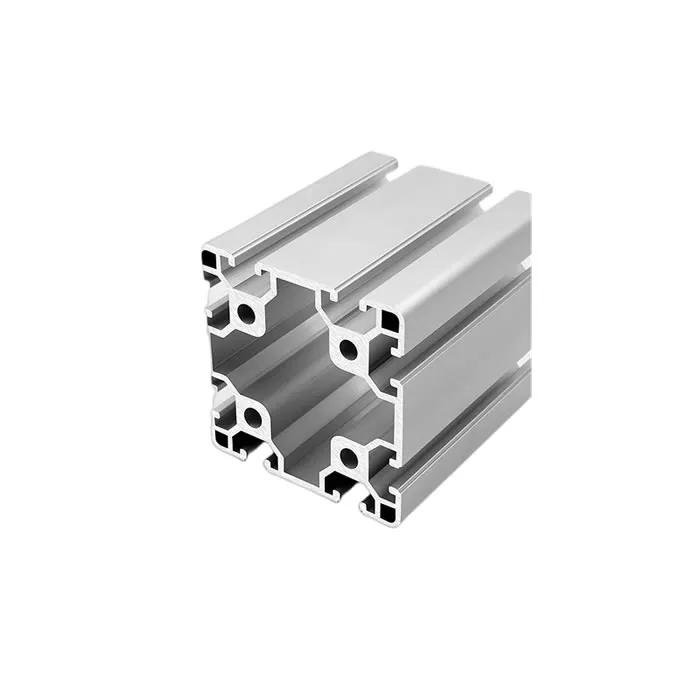

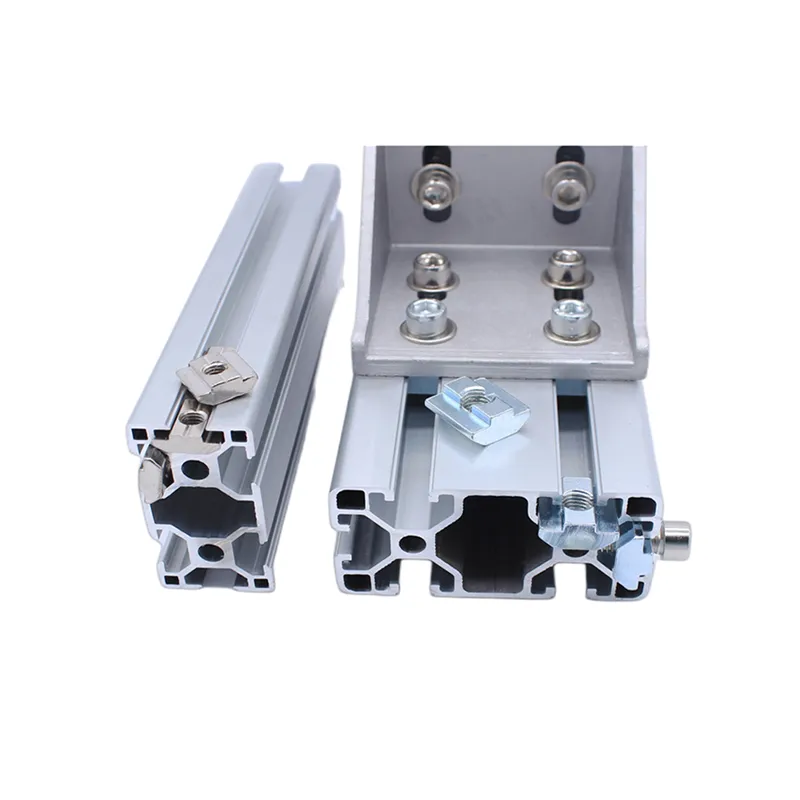

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS