How are ball screws manufactured

Ball Screws are commonly manufactured using two primary methods: rolling and grinding. Rolling is the preferred and

more economical method for producing precision ball screws, while grinding is used in specific situations

or when end machining features or tooling availability require it.

In the thread rolling process, heat-hardened dies are used to cold form the material without removing metal.

This efficient and cost-effective method follows similar principles as lead screw rolling. However, the thread form

for ball screws differs from lead screws due to the gothic arch shape

required to accommodate the rolling balls between the threads.

Ball screws are typically rolled from alloy steel or stainless steel grades that can be hardened through heat treatment.

The hardness of the material is crucial as it must withstand the load applied by hardened balls within the ball screw nut.

This hardness prevents excessive wear and material fatigue, ensuring long-lasting performance and preventing catastrophic failure.

One advantage of thread rolling for ball screws is its manufacturability.

Rolled ball screws are often formed in longer lengths, such as 12 feet, before being cut and machined.

Heat treatment can be applied to these long lengths with minimal concern about length-to-diameter ratios due to

through-feed rolling processes that apply pressure from different sides during forming. In contrast, grinding a

ball screw involves using a radial grinding wheel that can create bending or deflection issues if the length-to-diameter ratio

is too large. Support mechanisms like steady rests can minimize deflection but have limitations based on machine capabilities.

Precision rolled ball screw assemblies offer reduced backlash through a selective fit process.

Ball sizes are available in increments as small as 5 microns, allowing for precise matching of ball size

with pitch diameters of both the ball screw and nut assembly. This enables achieving

low-lash specifications comparable to ground ball screws.

Ground ball screw assemblies have even tighter backlash specifications and find application in scenarios

where less axial lash is required. However, they tend to be more expensive than precision rolled counterparts,

especially for longer lengths where costs may increase significantly.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

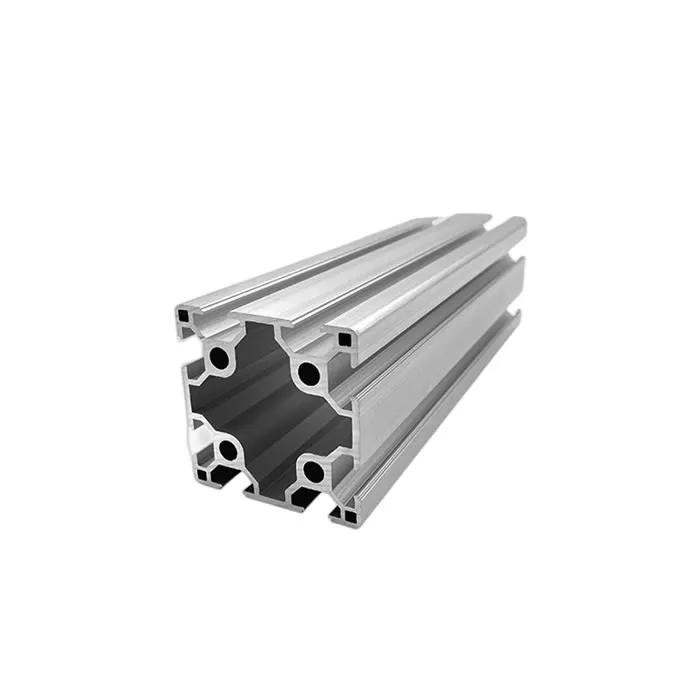

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS