Calculation of linear bearings

Calculation of bearing service life

Length life L=5 * [(FH * FT * Fc/Fw) * (C/Pc)] 3 ³ (Unit: 10km 10000 meters)

Basic rated dynamic load C (unit: Kg/kg)

When the working stroke is 1.5 times shorter than the bearing length, the shaft life is shorter than the bearing life.

When the stroke is 0.2-1.5 times the bearing length, the rated dynamic load is calculated based on the original 0.4-1.0 times.

The rated load of open end bearings when subjected to lateral force

and opening direction force is calculated based on one-third of the original

The working load Pc (calculated in Kg)

Hardness coefficient FH:

hardness HRC25 or above, FH=1.0; Hardness HRC52-58, FH=0.6-1.0.

Temperature coefficient FT:

When the working temperature is less than 100 ℃, FT=1.0;

Working temperature 100 ℃~125 ℃, Fr=1.0~0.95

Contact coefficient Fc

Install one set of bearings per shaft, Fc=1.0

Install two sets of bearings per shaft, Fc=0.81

Install three sets of bearings per shaft, Fo=0.72

Install four sets of bearings per shaft, Fc=0.66

Load factor FW

Operating speed less than 15 meters/minute, no impact, no vibration, Fw=1.0~1.5

Operating speed less than 60 meters per minute, minor impact or vibration, Fn=1.5-2.0

Operating speed less than 60 meters per minute, or with significant impact or vibration, Fw=2.0-5.0

Time lifespan LH=(10000 * L)/(2 * LS * n1 * 60) (unit: h hours)

L: Length lifespan (10000 meters),

LS: Working stroke (meters)

N1: Number of cycles per minute.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

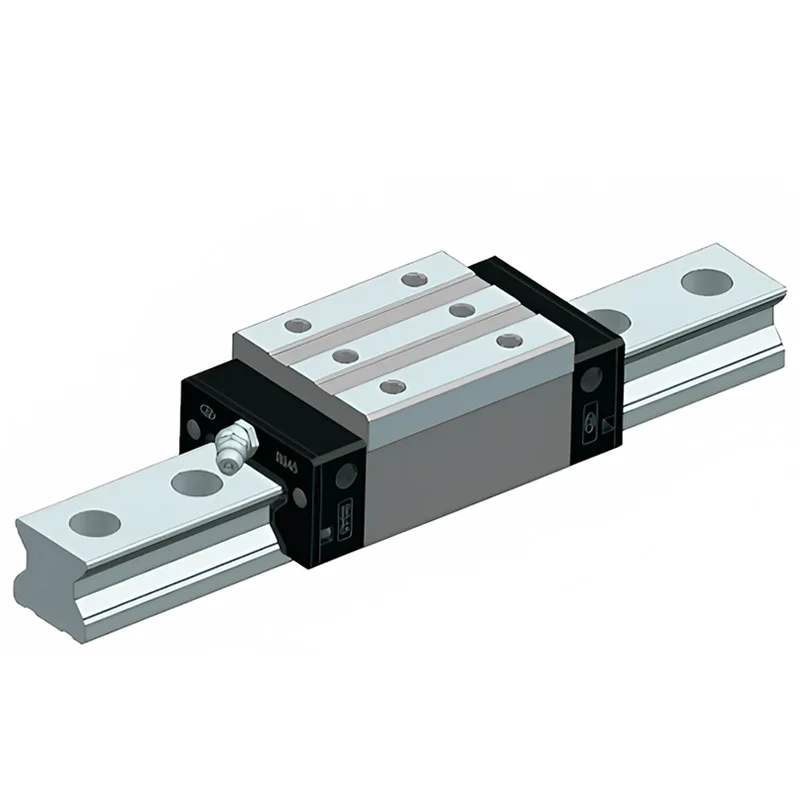

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd