Installing attachments on aluminum profile connector brackets

Aluminum profile connector brackets are a versatile solution for building frames and structures from aluminum profiles. Installing additional components onto these brackets is usually a simple process thanks to their pre-designed features.

This guide explores the common attachment methods for aluminum profile brackets:

Pre-drilled Holes and Slots:

Most brackets come equipped with pre-drilled holes or slots strategically placed for easy attachment of various components. These openings allow for a clean and efficient assembly process.

Attachment Methods:

The specific method for attaching components depends on the bracket design and the type of component being installed. Here are the common approaches:

Screws: This is the most common method. Screws of the appropriate size and thread type are inserted through the holes in the bracket and into the component, providing a secure connection.

Bolts: Some brackets have slots or larger openings designed for bolts. These offer a high degree of strength and stability, ideal for situations with significant weight or stress on the connection.

Specialized Fasteners: Certain brackets may require specific fasteners for optimal compatibility. These could include nuts and bolts of specific sizes or shapes, or specialized connectors designed to seamlessly integrate with the profiles and attachments.

Choosing the Right Method:

The most suitable attachment method depends on several factors:

Bracket Design: The pre-drilled holes, slots, or openings on the bracket will dictate the compatible fastener types (screws, bolts, etc.).

Component Type: The weight, size, and function of the component being attached will influence the necessary strength and stability of the connection. Heavier components might require bolts for increased support.

Structural Requirements: Consider the overall stress and load the connection will experience. Choose a method that ensures the assembled structure remains secure and stable under expected use.

By understanding these attachment methods and selection factors, you can efficiently and securely install various components onto your aluminum profile connector brackets, creating a sturdy and functional framework for your project.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

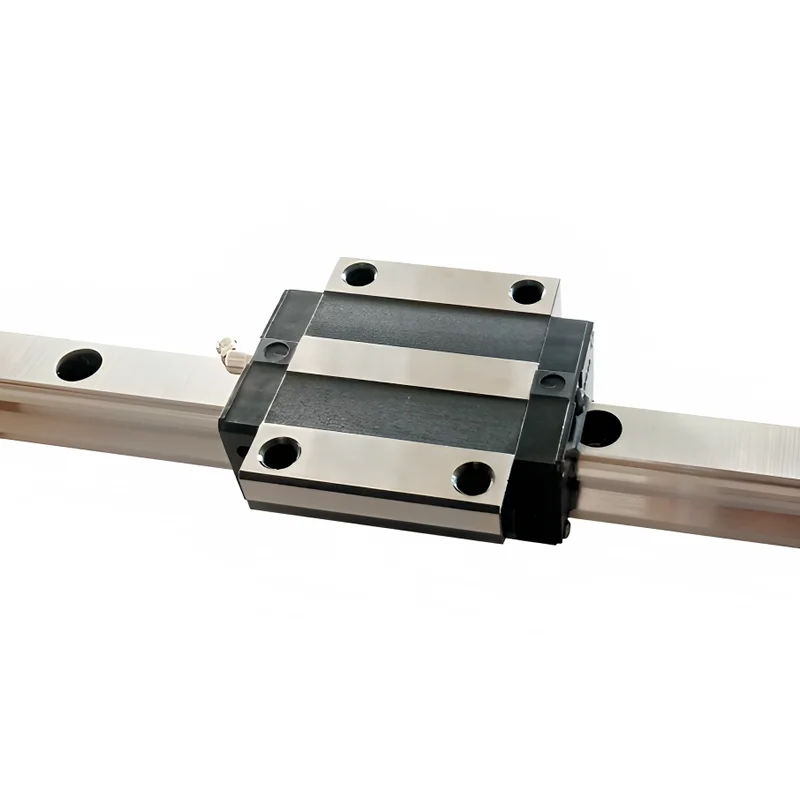

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

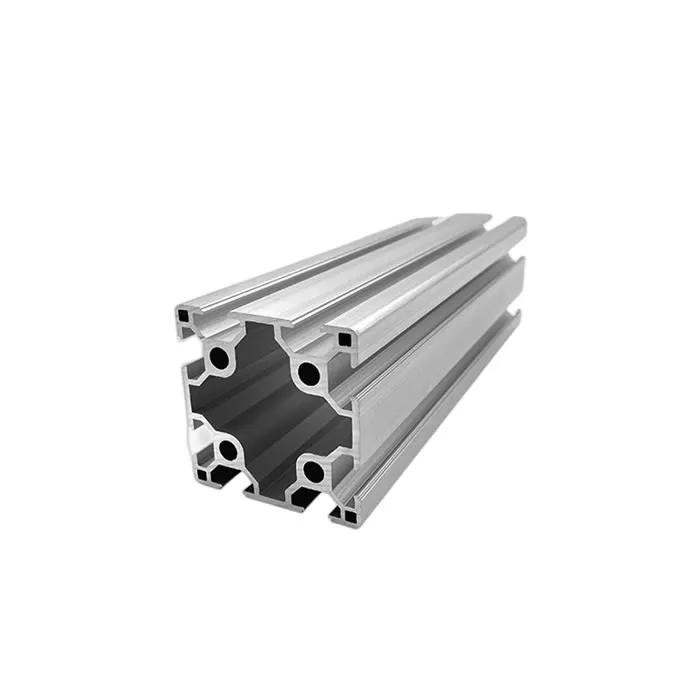

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd