Selection and Use of Linear Bearings

Linear Bearings are a low-cost linear motion system used

in conjunction with cylindrical shafts with infinite travel.

Due to the point contact between the bearing ball and the shaft, the load is small.

The steel ball rotates with minimal frictional resistance, allowing for high-precision smooth motion.

The linear motion provided by linear bearings is different from rotational motion.

Steel balls are used as rolling elements to perform circular motion on several closed

raceways inside the cylindrical bearing around the axis.

Linear motion ball bearings generally meet the following technical requirements:

1. Stable low friction motion, without crawling or vibration.

2. When a relative linear motion occurs between the bearing and the shaft, only a small force is required.

The above requirements and other special requirements can be achieved by correctly

using various types of linear motion ball bearings (standard, adjustable, and open).

The rings (excluding KH series) and steel balls of linear motion ball bearings are made of

GCr12 (SUJ2) bearing steel and 9Cr18 (SUS440C) stainless steel;

There are three types of retainers available: POM engineering plastic, low-carbon steel,

and stainless steel (usually supplied with bearing steel POM engineering plastic retainers);

The sealing ring is made of MBR nitrile rubber;

The unsealed iron cover is made of 65Mn spring steel and stainless steel;

The KH series ferrules are made of low-carbon steel through carbon nitrogen co infiltration.

The straight axis is determined by GCr15 Made of bearing steel, carbon steel and stainless steel

linear shafts can also be made according to customer needs.

The bearing seat, shaft support seat, and shaft support rail are made of stretched aluminum alloy (or die cast aluminum).

Selection of linear bearings: POM engineering plastic retainers are suitable

for working temperatures between -20 ℃ and 80 ℃;

The steel retainer is suitable for working temperatures between -40 ℃ and 125 ℃;

Stainless steel bearings are suitable for corrosive media such as water, steam, nitric acid, and vacuum working environments.

Installation of linear bearings: H7 and J7 grades are recommended for the hole difference of the bearing seat,

g6 and h ó grades are recommended for the tolerance of the linear shaft,

and the bearing installation must be pressed in with a step mandrel

(using strong tapping method may cause flange fracture or detachment);

The installation of the linear shaft must be aligned with the bearing hole and inserted gently.

If the shaft is tilted and inserted, it will cause the retainer to deform and the steel ball to fall off.

The installation direction of the bearing should be as shown in the figure,

which can improve the bearing capacity and extend the service life.

The bearing seat hole may compress the bearing, causing the clearance to decrease.

At this time, rotate the straight line by hand. If the shaft can contact the steel ball and rotate easily,

the clearance should be 0~+0.01mm; If there is a slight increase in force to rotate.

Moving, with a clearance of -0.01~0mm (already interference); If the applied force cannot rotate and the clearance exceeds 0.01mm,

the steel ball may slide simultaneously during rolling, which will reduce the service life of the bearing and shaft.

It can only be used under light load, low speed, and high centering requirements.

Measure the inner and outer diameters of adjustable and open type bearings before cutting.

There may be some elastic deformation after cutting,

and the clearance should be installed in the bearing seat for measurement

(similar to steel retainer bearings and KH bearings).

The adjustment direction of the bearing seat with adjustable clearance should be perpendicular

to the direction of the bearing cutting edge to ensure uniform clearance.

The structural characteristics of linear bearings cannot be rotated, and good guidance is required.

Therefore, linear bearings are generally used in a combination of

two shafts+four sets of bearings or two shafts+two sets of extended bearings.

The installation of the two shafts should be flat and straight.

After the entire combination is assembled, the transmission mechanism can only be installed flexibly

and without obstruction when pushed or pulled by hand, The transmission power should be sufficient to overcome

the frictional resistance of the bearings, and the frictional resistance of

linear bearings is approximately one thousandth of the working load.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

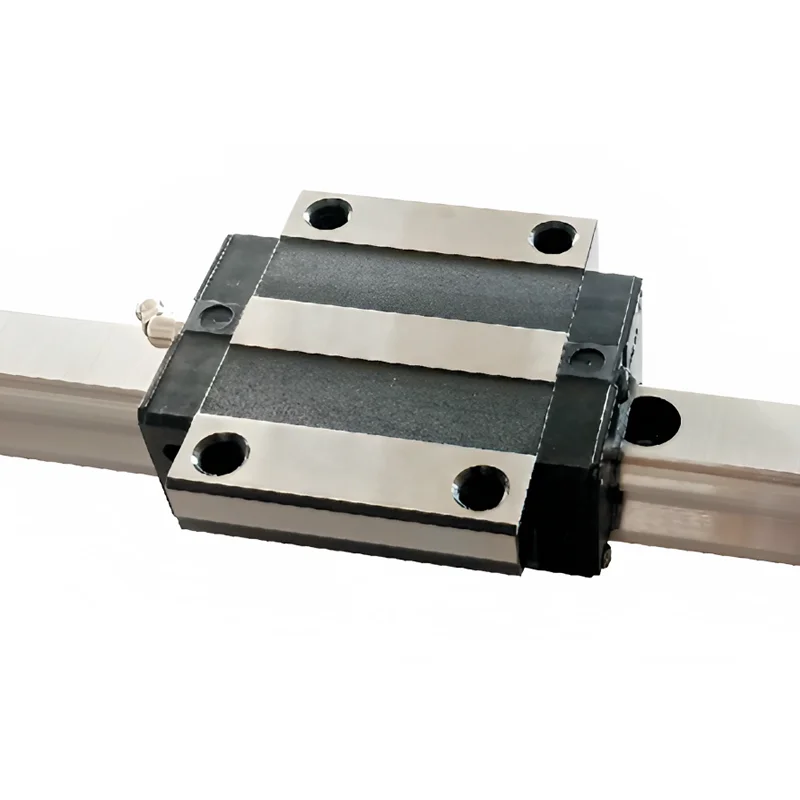

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS