Extending the Service Life of Aluminum Extrusion Fasteners

Aluminum fasteners offer a valuable combination of strength, weight savings, and corrosion resistance. However, to maximize their lifespan and performance, proper maintenance is crucial. Here are some key strategies to ensure your aluminum fasteners stay strong and reliable for years to come:

1. Material Matters

Start by selecting fasteners crafted from high-quality aluminum alloys known for their exceptional corrosion and oxidation resistance. This lays the foundation for long-lasting performance, especially in outdoor environments or applications exposed to moisture.

2. Lubrication

Friction is the enemy of any fastener. During installation and use, apply appropriate lubricants to minimize friction and prevent premature wear. Choose lubricants compatible with both the aluminum and the specific application.

3. Cleanliness is Key

Don't underestimate the power of cleanliness! Regularly inspect your aluminum fasteners and remove any accumulated dirt, grime, or debris. This prevents the build-up of corrosive materials that can damage the fasteners and compromise their integrity.

4. Don't Overload

Every fastener is designed for a specific load capacity. To avoid excessive stress and potential damage, ensure you always use aluminum fasteners within their designated load range. Overloading can lead to bending, breaking, or stripping of the threads, jeopardizing the entire connection.

5. Environmental Awareness

Aluminum fasteners perform best in moderate environments. Minimize exposure to extreme temperatures, high humidity, or harsh chemicals. These factors can accelerate corrosion and degrade the fasteners over time. If unavoidable, consider alternative materials or protective coatings for prolonged exposure.

6. Vigilance is Vital

Develop a routine for regularly checking the tightness of your aluminum fasteners. Over time, they may loosen due to vibration or settling. Retighten or replace them as necessary to maintain optimal stability and safety in your application.

By following these practices, you can ensure your aluminum fasteners function reliably and contribute to the long-term success of your project. Remember, proper maintenance is an investment that pays off in terms of safety, performance, and overall project longevity.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

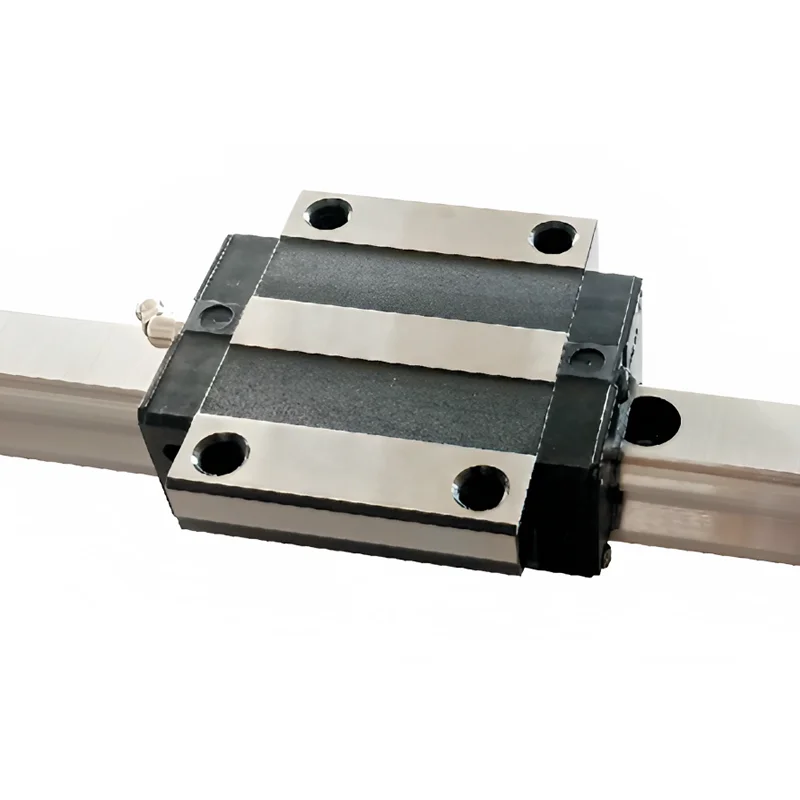

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS