Does the caster come with brakes or locking mechanisms

Casters can come with brakes or locking mechanisms.

These features are designed to provide stability and

prevent the object or equipment from moving when needed.

There are different types of brakes and locking mechanisms available for casters, including:

1. Total Lock Brake

This type of brake locks both the wheel rotation and swivel,

ensuring that the caster remains stationary.

2. Directional Lock Brake

This brake allows the caster to rotate freely but locks the direction of movement,

preventing the object from rolling in a specific direction.

3. Wheel Brake

This type of brake locks only the wheel,

allowing the caster to pivot and swivel while keeping the wheel from moving.

4. Top Plate Brake

Some casters have a built-in brake mechanism directly on the top plate,

allowing for easy and convenient locking and unlocking.

In conclusion, brakes and locking mechanisms are indispensable features of casters, offering enhanced stability and control in various applications. Whether it's the comprehensive immobilization provided by a total lock brake, the directional precision of a directional lock brake, or the selective wheel control of a wheel brake, each mechanism serves to prevent unintended movement and ensure safety. Additionally, top plate brakes offer convenience and ease of use by integrating the brake mechanism directly into the caster's design. By understanding the different types of brakes and locking mechanisms available, users can select the most suitable option to meet their specific needs, enhancing efficiency and safety in the handling of objects and equipment.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

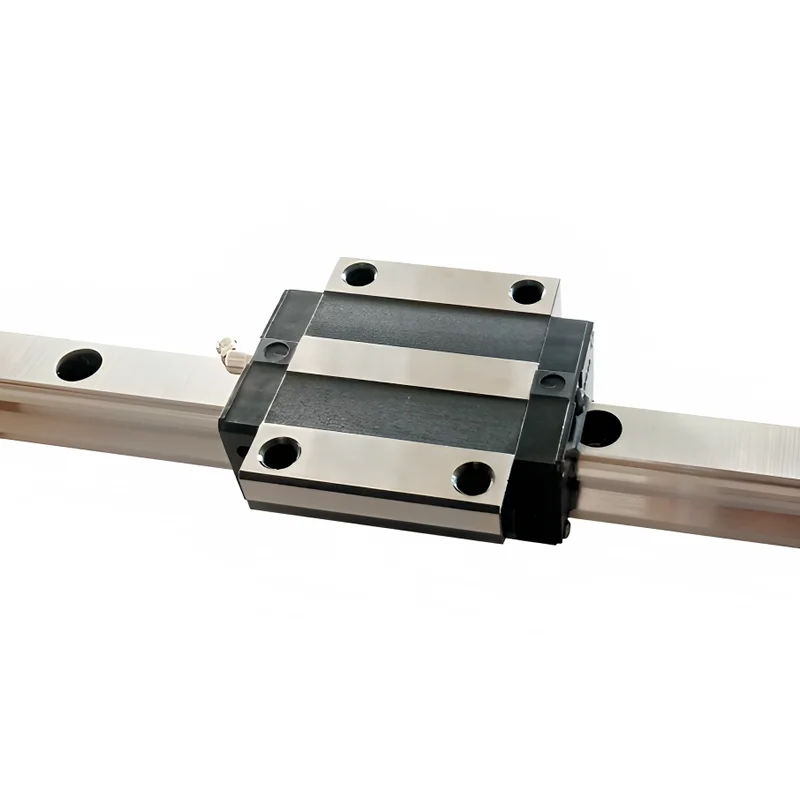

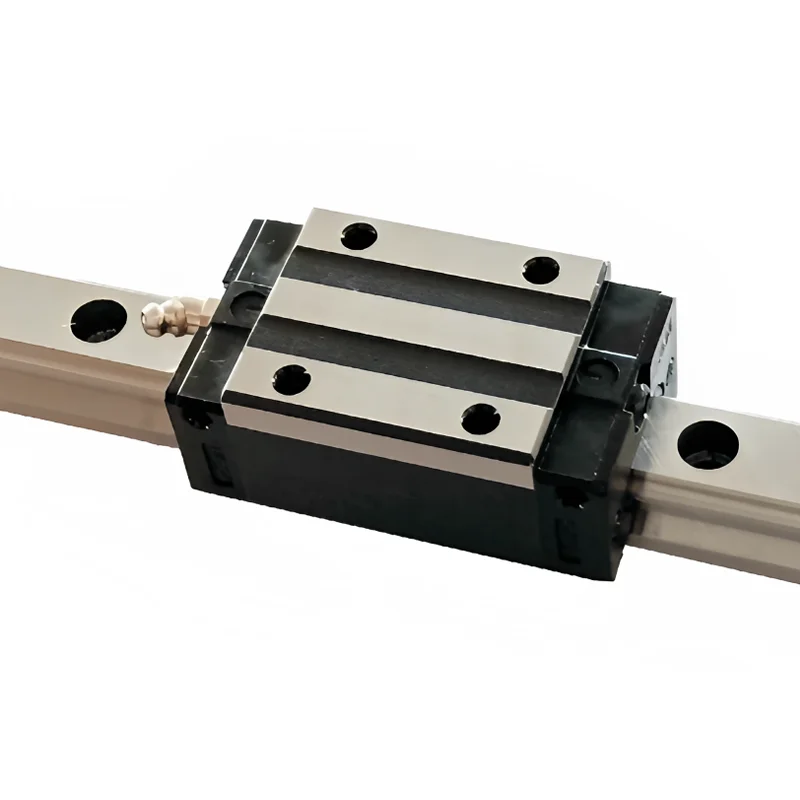

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

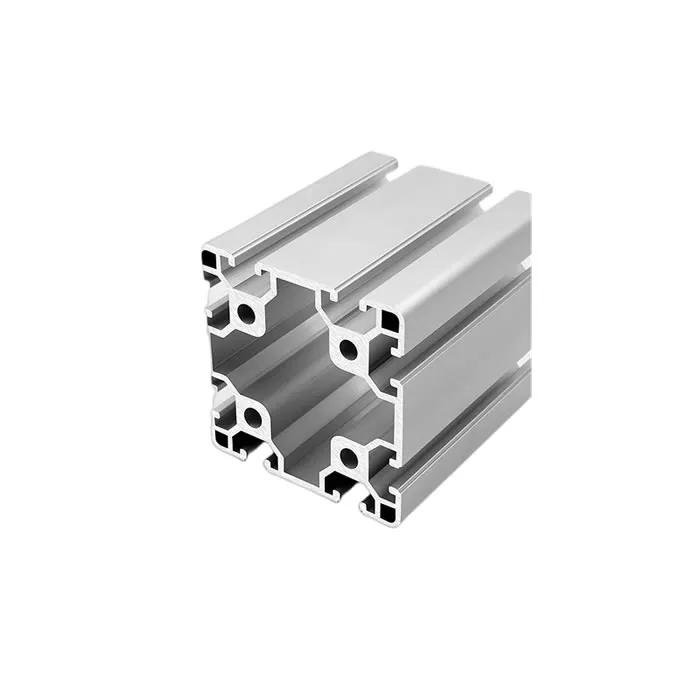

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd