6 Types of T-Slot Connection Methods

T-slot aluminum extrusions are a versatile building material used for various projects, from machine frames to workstations and enclosures. The beauty of these extrusions lies in their ease of assembly using various T-slot connection methods. Here are 6 of the most common ones:

1. Corner Brackets: As the name suggests, corner brackets are L-shaped metal pieces that connect two T-slot extrusions at a 90-degree angle. They are typically bolted onto the extrusions using screws threaded into the T-slots. Corner brackets are a simple and strong solution for creating rigid frames.

2. Embedded Connectors: Unlike corner brackets that are bolted externally, embedded connectors fit snugly inside the T-slot profile. They provide a clean and aesthetically pleasing connection, ideal for applications where appearance matters. Embedded connectors come in various shapes and sizes to accommodate different connection angles.

3. T-Groove Connectors: T-groove connectors are three-way or four-way connectors that slide into the T-slots of extrusions, allowing them to join at various angles. They are secured using setscrews that tighten against the inner wall of the T-slot. T-groove connectors offer a high degree of flexibility for creating complex structures.

4. Three-Dimensional Corner Connectors: Three-dimensional corner connectors are specialized connectors designed to join T-slot extrusions at non-orthogonal angles. They offer more versatility than standard corner brackets and are particularly useful for building frames with angled sides or curved sections.

5. Active Hinge Connectors: Active hinge connectors allow for the creation of adjustable joints within a T-slot frame. They typically incorporate a hinge mechanism that enables one extrusion to pivot relative to another. This feature is useful for building adjustable workstations, machine enclosures with access doors, or even robotic arms.

6. Combination Connection Method: The beauty of T-slot systems lies in their modularity. You can combine different connection methods to achieve your project's desired functionality and aesthetics. For instance, you can use a combination of corner brackets for a strong frame and embedded connectors for specific sections that require a clean look.

The best T-slot connection method for your project depends on various factors, including the required strength, desired aesthetics, and the complexity of the structure. Consider these factors when choosing the most suitable connectors for your T-slot aluminum project.

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

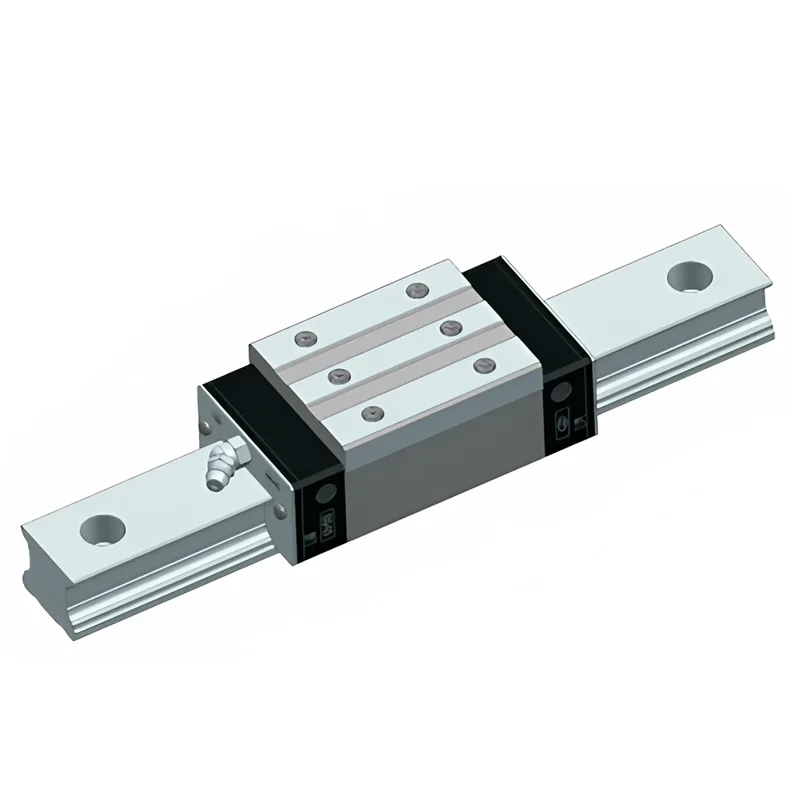

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS

Enhance Industrial Efficiency with Premium Cylinder End Bearings from SAIVS