Conveyor Pulleys | Overhead Conveyors Needle Roller Bearings: Reliable Movement in Manufacturing Plants

1.KR design cam followers are fitted with a needle roller and cage assembly.

They are also available with a full complement needle roller set, which is identified by the letter V at the end of the basic designation.

The outer ring is axially guided by the pressed-on flange ring and the head of the stud, which also serves as an integral flange.

2. KR design cam followers without a designation suffix or with the designation suffix B

have a narrow gap between the outer ring and the two flanges that serves as a gap-type seal.

3. KR design cam followers are also available with an axial sliding ring made of PA66 on both sides,

identified by the designation suffix PPA , PPSKA or PPXA. In the radial direction,

the sliding ring forms a narrow labyrinth seal with the outer ring to protect against coarse contaminants.

In the axial direction, the sliding ring serves as a contact seal to reliably retain grease in the bearing.

This improves the lubrication conditions in the bearing, keeps friction and frictional heat low, and extends grease life.

Product feature:

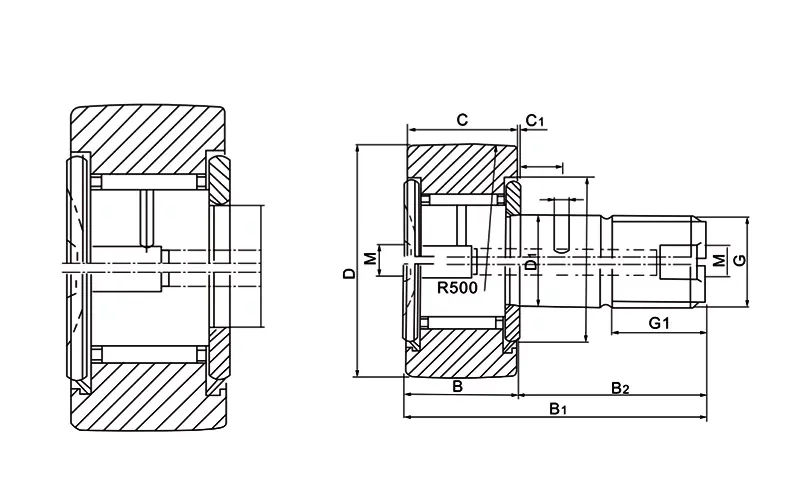

Instead of an inner ring, cam followers have a solid stud (pin) that is threaded so that the cam follower

can be quickly and easily attached to appropriate machine components by means of a hexagonal nut.

All three cam follower designs have the same main dimensions. The differences are in their internal design,

which make them suitable for various operating conditions. In contrast to ball and roller bearings,

where the bearing size refers to the bore diameter d, for cam followers the size refers to their outside diameter D.

All designs are available with a concentric seat (fig. 1) or an eccentric collar (fig. 2) on the stud.

An eccentric collar, which has a shrink-fit onto the stud,

enables less stringent positioning tolerances to be specified for associated components.

The values for the adjustable eccentricity are listed in the product tables.

An eccentric collar is identified by the letter E at the end of the basic designation.

Stud type track roller (cam follower) - KR

- crowned OD

- cylindrical OD is avaible , suffix " X "

- hex wrench socket in stud head

- full needle rollers design is also available ( prefix " KRV " )

- stainless steel 440C is also available ( prefix " SS " )

- two shields is also avaialbe ( suffix " PP " )

Cam follower needle track roller bearing Wheel and pin bearing needle bearing

Application of cam followers:

Escalator;Moving sidewalk;Elevator;Conveyor system;Lifting machinery;

Automotive line machinery;Material handling equipments;Linear motion guidance equipments;Cam drives;Screw drives;

•Note:when bearing of series KR,KRV with eccentric, then designation of earing KRE,KRVE.

•Note:*outersurface an be cylinder of spherical.** Limits of chamfer depend on the design.