Lubrication Of Linear Guideways

Lubrication

Supplying insufficient lubrication to the guidewaywill greatly reduce

the service life due to an increasein rolling friction.

The lubricant provides the following functions.

1.Reduces the rolling friction between the contact surfaces

to avoid abrasion and surface burning ofthe guideway.

2.Generates a lubricant film between the rolling surfaces and decreases fatigue.

3.Anti-corrosion.

Grease

Linear guideway must be lubricated with the lithium soap based grease berore installati on.

After the linearguideway is installed,

we recommend that the guideway bere-lubricated every 100 km.

It is possible tocarry out the lubrication through the grease nipple.

Generally, grease is applied for speeds that do not exceed

60 m/min faster speeds will require high-viscosity oil as a lubricant.

Oil

The recommended viscosity of oil is about 32-150cSt The standard grease nipple

may be replaced byan oil piping joint for oil lubrication.

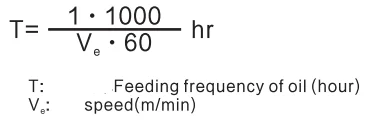

Since oil evaporates quicker than grease, the recommended oil feedrate is approximate 0.3cm³/hr.

How to avoid roller bearing failures

How to avoid roller bearing failures

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

Why Precision Ball Screws are Vital for Industrial Automation and How to Choose the Right Supplier

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

SAIVS Linear Motion Ball Slide Units – Precision and Reliability for Your CNC Needs

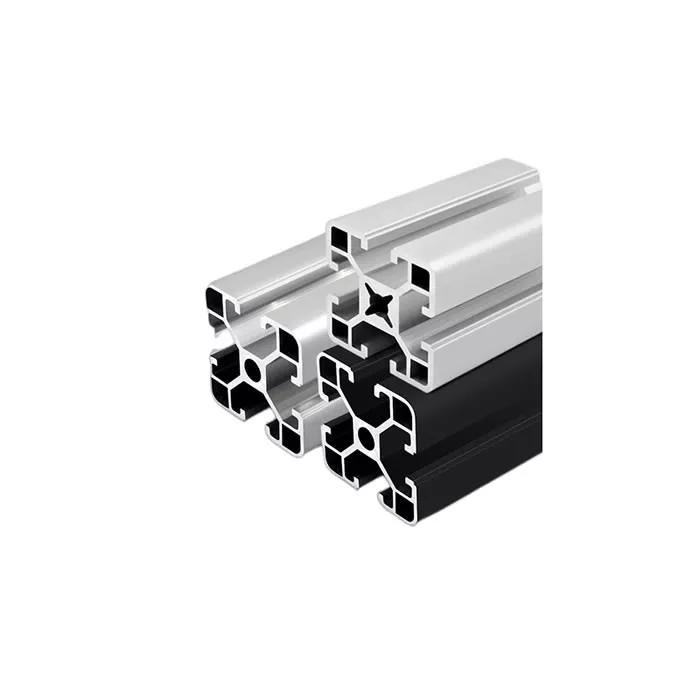

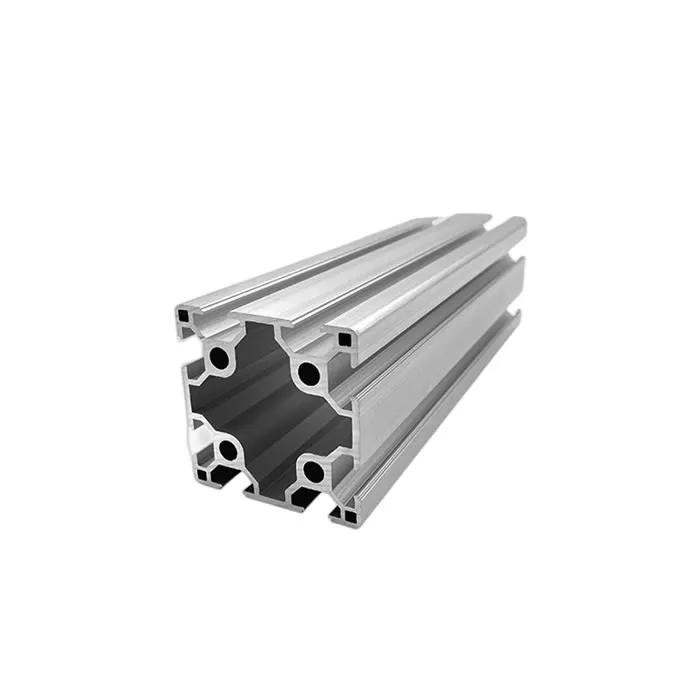

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd

High - Quality T - Slot Aluminum Extrusion Profiles from Ningbo SAIVS Machinery Co., Ltd